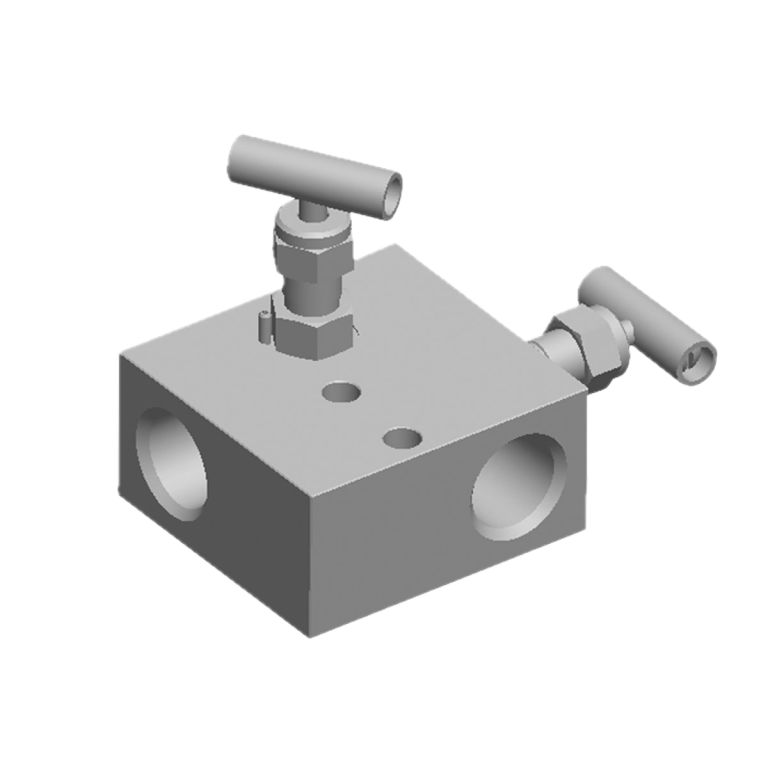

The KPT two-valve manifolds are used primarily to calibrate static pressure transmitters, switches, or gauges. All necessary hardware including a shutoff valve, calibration valve, tee, and other tubing are all contained in one product. The KPT series of manifolds are available with either replaceable soft seats or an integral metal seat. The KPTM manifold includes a special valve seat that can be converted from a hard or metal seat to a soft seat by simply removing two washers. The KPT7 manifold is intended for high temperature applications. It has an integral metal seat.

Features/Benefits:

- Bubble-tight shutoff. Every valve is 100% tested.

- Space-saving design. One compact valve replaces two. Fewer connections means less leak paths means less fugitive emissions.

- Cost-saving design. Less parts means lower cost in the order of 20-30% compared to conventional two-valve installation.

- Stem threads isolated from the process fluid, eliminating process fluid contamination, lubricant washout and thread corrosion.

- Mirror finish stems enable smooth stem operation and extended packing life.

- Rolled threads on the stem and in the bonnet increase strength, reduce galling and extend the service life of the valve.

- Adjustable packing adjusts easily, increasing valve life and reducing downtime for packing replacement.

- Multiple packing options available including Teflon® and GRAFOIL®.