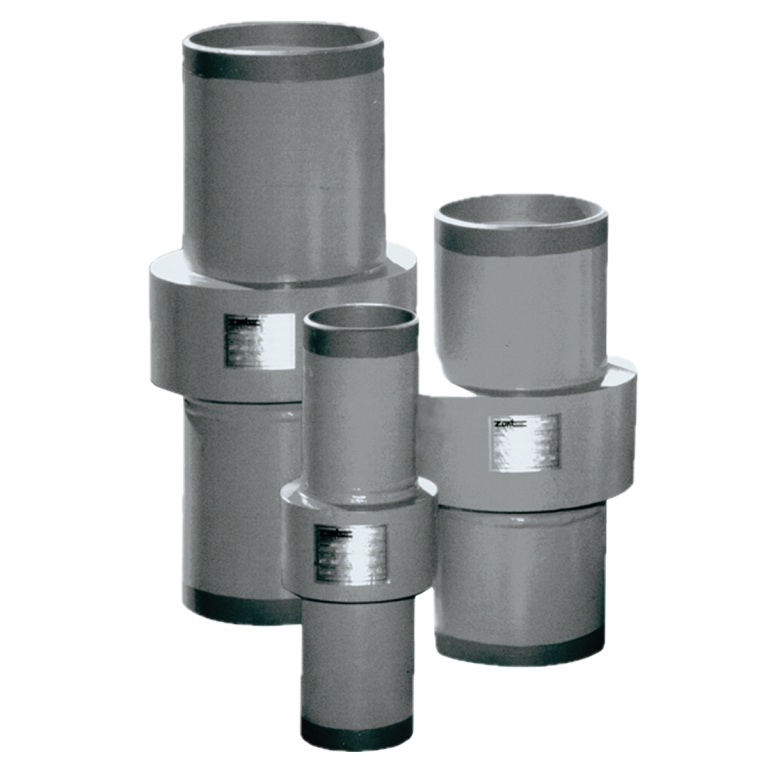

The Kerotest Zunt Insulating Joints are manufactured to ISO 9001 standards. This solid weld design is more economical and comes in a broader range than any previous insulating joint from Kerotest…from 1/2-inch to 120-inch and over, ANSI 150 to 2500. There is no assembly required and no maintenance.

Features/Benefits:

- Compact design

- Low profile

- Complete range of sizes and pressure classes

- Each joint is internally lined with epoxy resin to effectively prevent bridging of the insulating gap

- Weld preps are per API 5L (ANSI B16.25 available upon request)

- All welding processes are in accordance with ASME VIII and IX

- Manufactured to applicable ANSI, ASTM, ASME, AISI, API, IEC, and ISO standards

- Each joint is factory tested to verify the mechanical integrity and electrical resistance to satisfy cathodic protection requirements

- Manufactured to ISO 9001 quality standards

- Epoxy coated

- Eliminates electrical shorts and stops stray current in a pipeline system

- Most economical and reliable method that can be used to cathodically protect a pipeline system

- Can be installed above or below ground

- Reduced installation time (just to welds), eliminates field assembly of bulky insulated flanges and bolted couplings

- Long term electrical resistance does not depend on installers assembly of an insulation kit

- Eliminates costly maintenance to field repair flange leaks and electrical shorts