C5 Process Group

Practical, thoughtful and sustainable. A responsible partner for your ESG goals.

C5 designs and fabricates the highest quality products in the energy industry. We deliver first-in-class solutions to today’s oil, gas, petrochemical, and power providers.

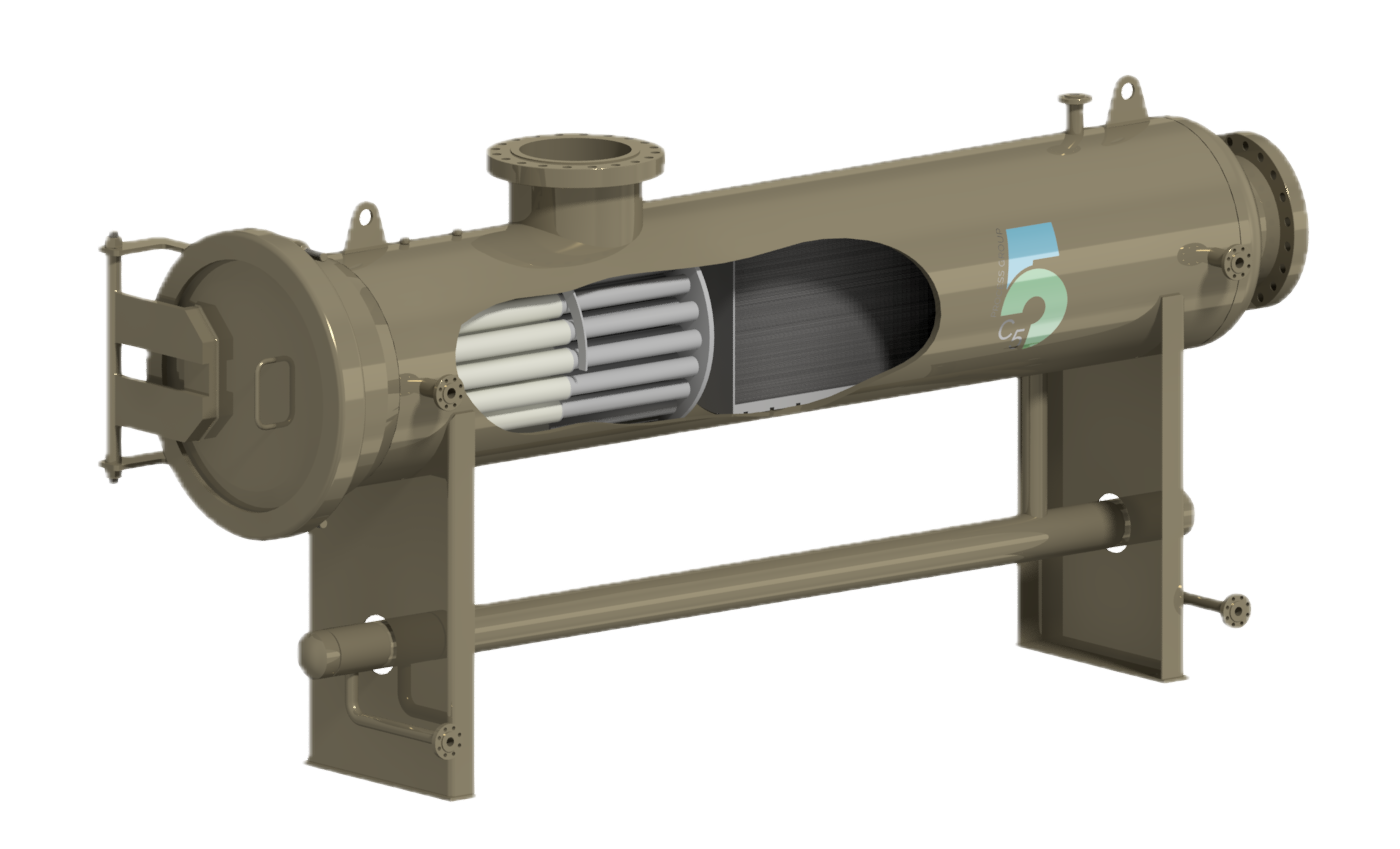

Particulate removal from 0.3 micron to 5 microns.

The components of a filter separator/coalescer include a vessel to house the filter elements, a quick opening closure, and mist extraction. The differences between whether a filter is a separator or a coalescer depends upon the direction of gas flow through the filter elements and the presence of pre- or post-mist elimination devices. Mist elimination devices are generally: double pocket vane or single vane packs or mesh pads or combo-vane-mesh packs. Filter separators can be configured either vertically or horizontally.

Manufactured to achieve your needs on time and on budget.

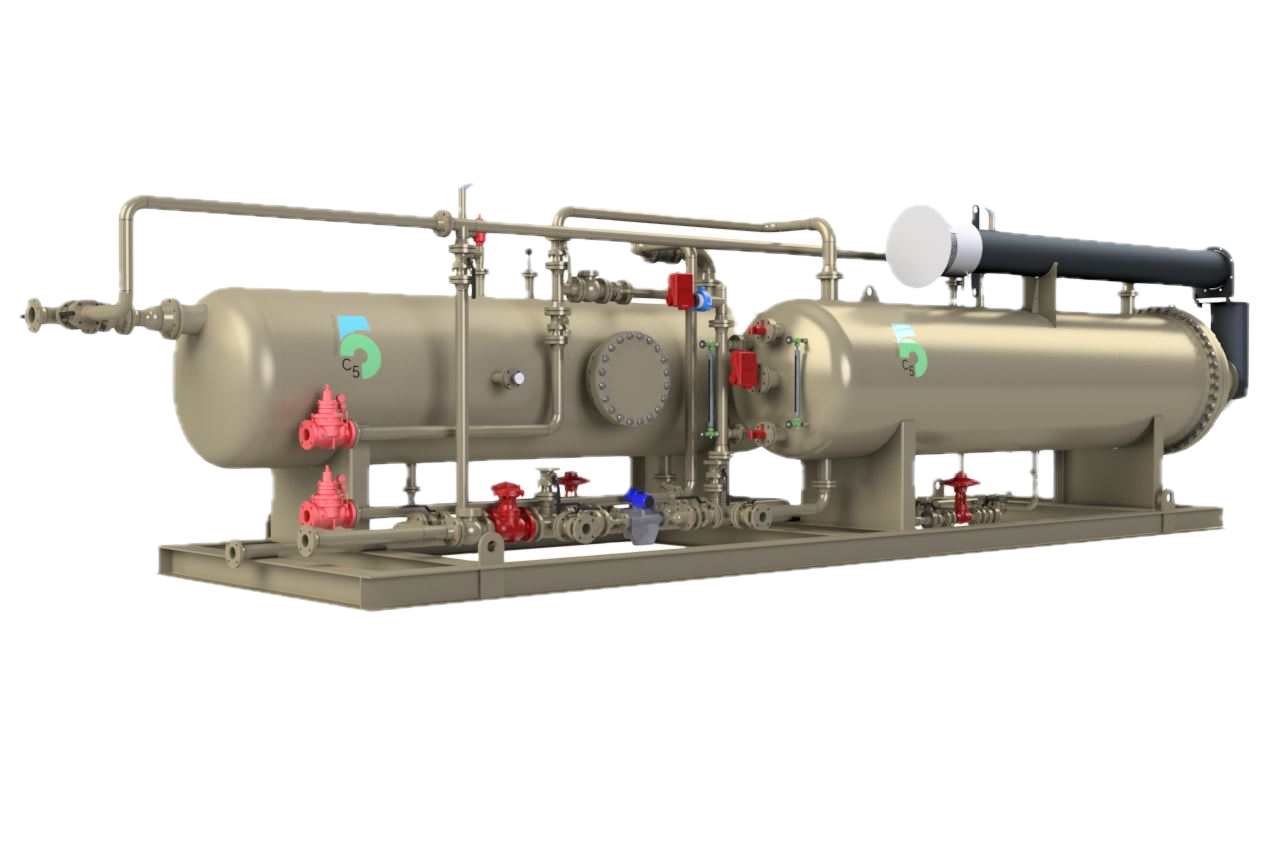

C5PG provides equipment to remove water from crude oil. Treating elements include heat, supplemental coalescing devices, and gravity settling. Typical treaters include corrugated plates, mesh pads, perforated plates, and slotted baffles. Treaters can be configured either horizontally or vertically, with U-type firetubes in the heating section and coalescing devices in the treating section.

Clear vision and progressive thinking.

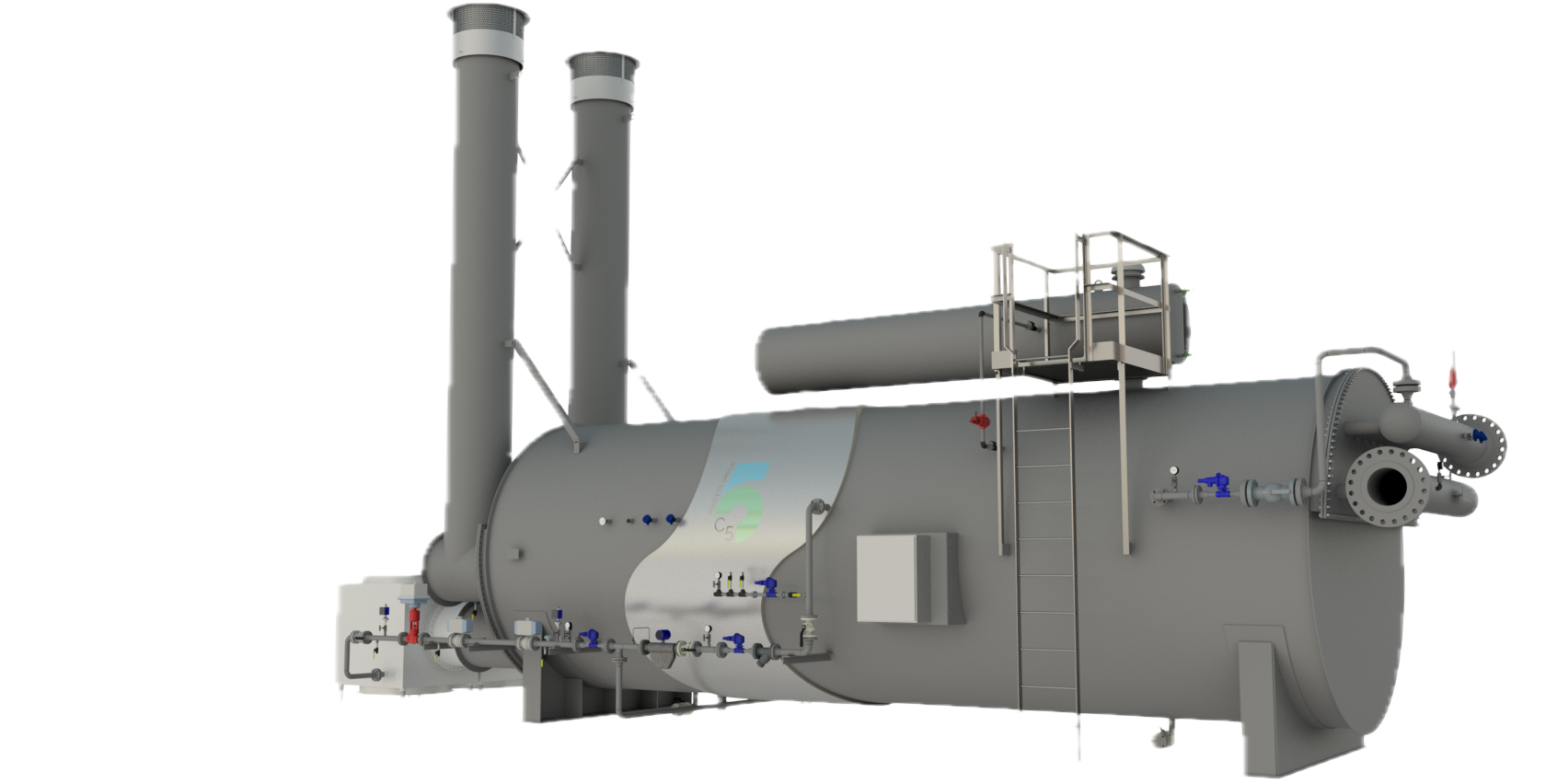

Indirect heating is the safest way to heat hydrocarbons, ensuring flammable gases are warmed by an inert heat medium, typically propylene or ethylene glycol, rather than direct contact with a flame. Line heaters, dew point heaters, bath heaters, indirect heaters.