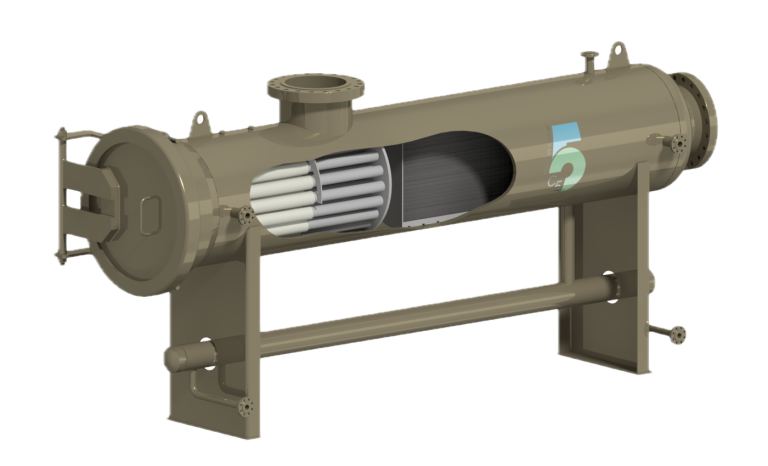

C5 Process Group, Inc. (C5PG) provides treatment systems to process and remove particulates and liquids from gas streams. The process equipment consists of stand-alone vessels or skid-mounted modules.

The components of a filter separator/coalescer include a vessel to house the filter elements, a quick opening closure, and mist extraction. The differences between whether a filter is a separator or a coalescer depends upon the direction of gas flow through the filter elements and the presence of pre- or post-mist elimination devices. Mist elimination devices are generally: double pocket vane or single vane packs or mesh pads or combo-vane-mesh packs. Filter separators can be configured either vertically or horizontally.

The particulate removal can be from 0.3 micron to 5 microns. Liquid droplet removal requires coalescing the liquid prior to separation.