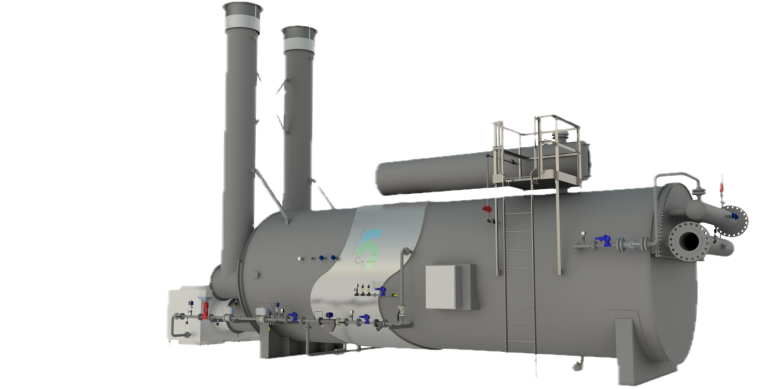

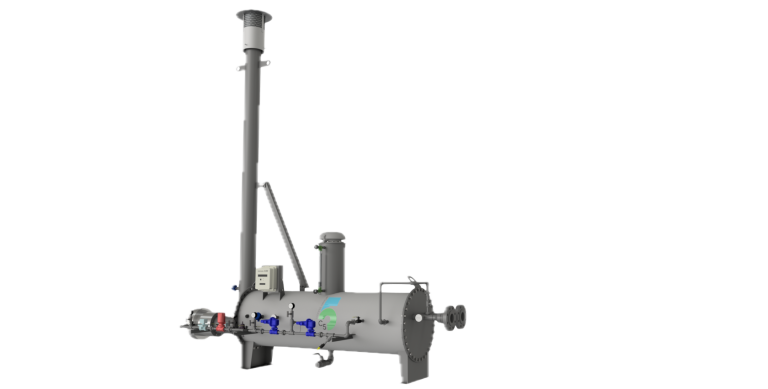

C5 Process Group, Inc. (C5PG) designs, fabricates and commissions indirect, water bath heaters for the oil, gas storage, gas transmission and utility industries.

Indirect heating is the safest way to heat hydrocarbons, ensuring flammable gases are warmed by an inert heat medium, typically propylene or ethylene glycol, rather than direct contact with a flame. Line heaters, dew point heaters, bath heaters, indirect heaters.

Water bath heater properties:

- Uniform heating from the bath media

- Removable firetube and process coil

- Convective heat transfer

- Ethylene glycol, propylene glycol or other heat mediums

- Flammable process streams are completely isolated from an ignition source

- Long firetube life

- Vessel operates at atmospheric pressure

- Heat duties ranging from 500,000 Btu/hr to 20,000,000 Btu/hr