A+ Corporation

Connecting engineering knowledge and software.

Sampling applications can vary wildly due to gas quality, geographic location, and other factors, so why are so many sampling systems one-size-fits-all solutions? A+ considers all application factors when designing your sampling system to keep your system as simple as possible while still delivering an Analytically Correct sample to your analyzer.

- GPR Probe Regulator

- GP2 Membrane Probe

- GPSD™

- Model 120

- Model 123

- Model 701

- Model 702

- Model 750

- Model 755™

- Avenger™ Model 38M

- Avenger™ Model 91

- Avenger™ Model 33

- Avenger™ Model 33M

- Tornado™ Model 602

- Model GHR™

- Model GR™

- Model JTR-H™

- Model JTR™

- DaVinci™ Modular ADP

- ACES™

Helps to preserve sample integrity.

Liquid carry over from the pipeline into the sample conditioning system should be prevented when sampling natural gas as it can directly impact the accuracy of the compositional analysis and also damage the analyzer. Genie Probes™ provide a means to insert Genie Membrane Technology™ directly into a pipeline for the purpose of separating unwanted liquid and particulate from the gas sample at flowing temperature and pressure conditions, in compliance with industry standards.

The safest and most versatile probes available on the market.

The GP2™ probe consists of a housing and a membrane tip probe. The housing is installed in a depressurized pipeline through a vertically mounted thread-o-let or flange, and contains a “foot valve” in its lower end. Inserting the probe into the housing opens the “foot valve”, allowing pipeline gas to flow freely through the membrane. Retracting the probe from the housing closes the foot valve, making it possible to perform probe maintenance without depressurizing the pipeline. This insertion/retraction method is considerably less expensive and complex than pneumatic or hydraulic methods.

Membrane small diameter probe.

The GPSD™ is designed specifically for small diameter 2” or 3” pipelines. The GPSD™ uses proven Genie® Membrane Technology™ to extract a representative gas sample and provide a safety net for protecting gas analyzers against liquid damage. This model’s housing is designed to install in a depressurized line. Once installed, the housing includes a foot valve in its base, so the probe can be inserted or retracted with a pressurized line or vessel. The GPSD™ replaces the threaded foot valve (-T) housing option of the GPR™.

A simple, safe, and economical solution.

The Model 120 is ideal for low flow applications and can withstand high pressure in the housing. This high pressure model has a 1” cross sectional membrane area, the same as the original Genie® Model 101, and it is ideal for the removal of relatively small amounts of liquid present on a continuous basis; it is also perfect for protecting gas chromatographs, mass spectrometers, O2 analyzers, moisture analyzers, and other analyzers with relatively small flow requirements. Please note that special fittings may be ordered, such as a Universal Assembly™. Additional information such as FAQs is available.

Known for sample conditioning and analyzer protection.

The Model 123 is ideal for applications requiring higher flow rates or larger quantities of liquid than the Genie® Supreme Model 120 can withstand. It offers a 2” diameter membrane, the same membrane cross sectional area as the original Genie® Model 130 or Genie® Model 130M, and is ideal for removing continuous liquid flow from gas samples. It is also perfect for protecting components such as on-line analyzers, gas chromatographs, or mass spectrometers. Additional information such as FAQs is available.

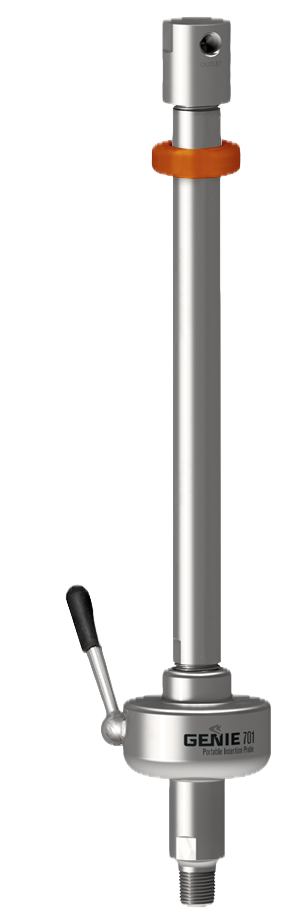

Field proven and patented.

Our Genie Model 701 Portable Insertion Probe is a simple, safe and economical solution to extract a representative vapor phase sample from a gas source. Our exclusive Pressure Balance™ technique allows for effortless insertion of the probe without the need for additional tools or pneumatic and hydraulic methods. Inserting the probe is easily accomplished by simply turning the handle with fingertips. This probe’s lightweight design makes it ideal for use as a spot or portable analyzer sample probe.

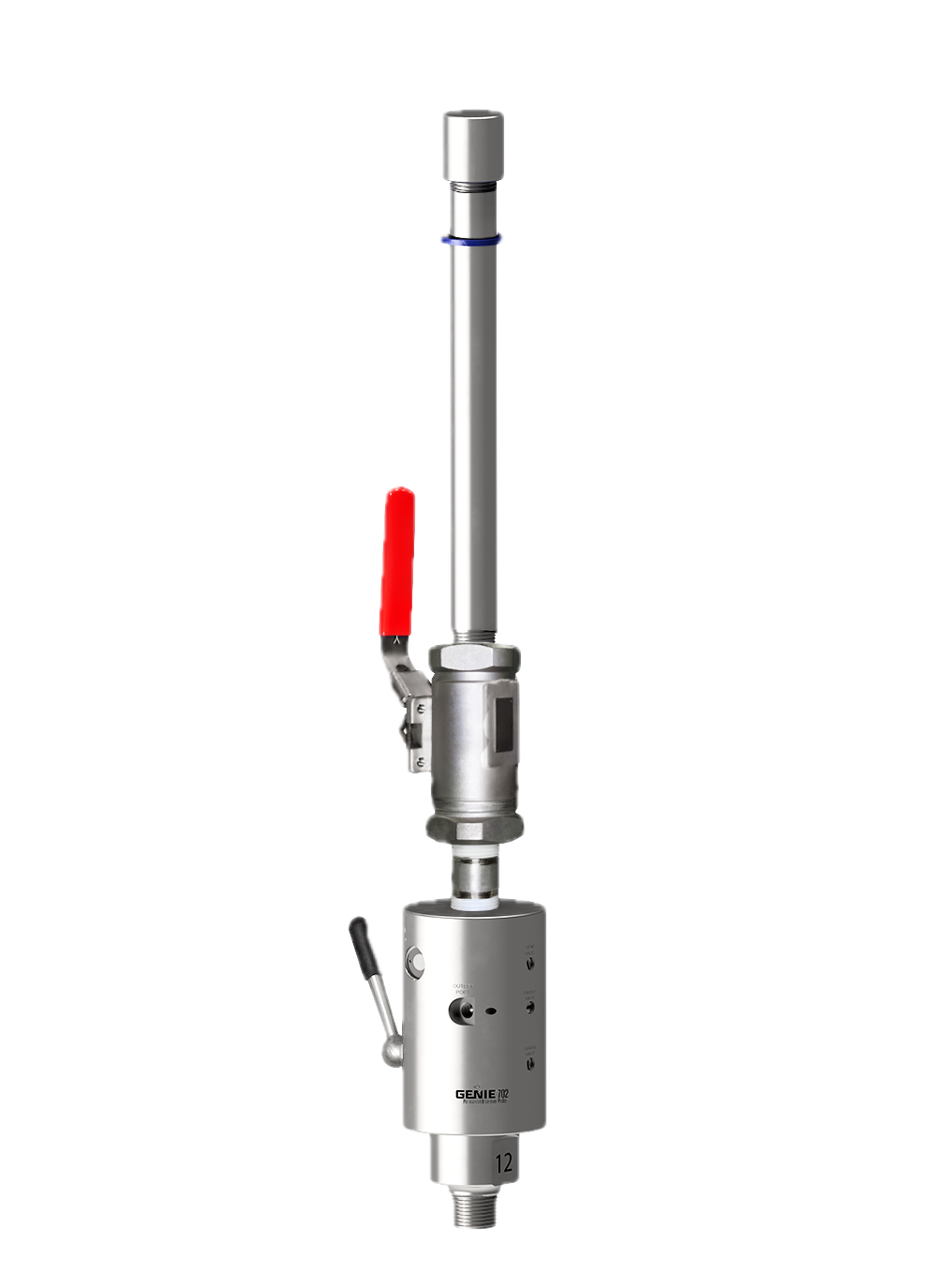

Large enough for a 10’ install, yet small enough to fit in an enclosure.

The Genie Model 702 Permanent Insertion Probe™ is a simple, safe and economical solution to extract a representative vapor phase sample from a gas source. The 702 is designed for sampling at a specific depth in a pressurized pipeline; each length is customized up to 10 feet to fit your application. Our exclusive Pressure Balance™ technique allows you to effortlessly insert the probe without the need for additional tools or pneumatic and hydraulic methods. Once inserted, the installation housing can be replaced with a shorter one to accommodate partial retraction of the probe during pigging operations or placement into heated enclosures.

Simple and straightforward installation.

The Model 750 is an adjustable length, membrane tip probe designed to sample transmission quality natural gas. It can be inserted and extracted from a pressurized line through a full opening valve without the use of a special insertion device. This probe is offered with optional coatings from Silcotek™. The Model 750 installation process is simple and straight forward. A low internal volume option is available for trace measurement applications or low sample flow rates.

Complies with industry standards.

The Model 755™ is an adjustable length, membrane tip probe regulator designed to sample transmission quality natural gas. The pressure regulator is built into the probe immediately downstream of the membrane, inside of the pipeline. Heat is transferred from the flowing pipeline gas to the regulator to prevent excessive JouleThomson cooling, helping to prevent condensation during pressure letdown.

High performance filters with the utmost flexibility.

The Avenger™ 30 Series sample filters are easy to install and maintain, especially in heated, densely populated cabinets. The uniquely designed filter housing allows service to the filter element/membrane by simply removing the bowl without disassembly of the fittings. The Avenger™ Model 38M is the same size as the Model 38, and contains Genie Membrane Technology™. The Liquid Block™ is on option for this model. When compared to the Models 33 and 33M, the Model 38M is smaller in size and internal volume making it better suited for lower flow applications.

The utmost flexibility for coalescing and particulate filtration needs.

The Avenger™ 91 Coalescing and Particulate Filters provide the utmost in flexibility for your coalescing and particulate filtration needs. The conventional 3-port model is a direct replacement for competitive vertically mounted sample filters. However, the 5-port model, with its two different porting configurations allows for greater mounting and application flexibility. These filters were specifically designed for analyzer sample conditioning applications by analyzer sample conditioning specialists.

High performance filters.

The Avenger™ Model 33 is the same size as the Model 33M. Unlike the Model 33M, the Model 33 does not include Genie Membrane Technology™ or Liquid Block™. If either of these features are desired, the Model 33M should be selected. When compared to the Models 38 and 38M, the Model 33 is larger in size and internal volume, making it better suited for applications requiring higher flow rates or containing larger amounts of contaminants than the Models 38 and 38M can handle. In addition to gas sampling applications, the Model 33 can also be used as a particulate filter in liquid sampling applications.

Sample conditioning and analyzer protection.

The Avenger™ Model 33M is the same size as the Model 33, and contains Genie Membrane Technology™. The Liquid Block™ is on option for this model. When compared to the Models 38 and 38M, the Model 33M is larger in size and internal volume, making it better suited for applications requiring higher flow rates or containing larger amounts of contaminants than the Models 38 and 38M can handle.

Highly efficient, self-cleaning liquid bypass filters.

The Tornado™ Model 602 is a continuously self-cleaning filter that protects analyzers from particulate in liquid samples. In normal operation, components of interest flow through the Tornado’s element to the analyzer. Contaminants are shed by the element and removed through the Bypass port. The G.U.T.S.™ (Genie® Ultimate Thermoplastic Seal) gasket is an excellent alternative to expensive elastomers. It withstands radical temperature cycles without leaks due to its ability to maintain a bubble-tight seal even when thermocycled repeatedly from 0-300ºF. The multi-layer filter media consists of the support screen and flow screen. This results in more efficiency and easier installation and handling. The elements are self-cleaned by the tornadic flow of sample across them. The self-cleaning action is best when the bypass flow rate is maximized, the outlet flow rate minimized, and variations in element rating are tried.

Robust heat transfer technology.

The Model GHR™ is a single-stage heated pressure regulator designed specifically for use in gas analytical systems. The GHR™ prevents condensation of the sample gas from occurring as a result of Joule-Thomson (JT) cooling during the pressure reduction process of high pressure and high dew point gases or due to low operating or ambient temperature conditions.

The GHR™ is designed with a long, spiral flow path including pre and post regulation heat exchangers that provide efficient heat transfer which preserves sample integrity. The first heat exchanger preheats the gas sample above its dew point temperature; preventing condensation during pressure reduction. The second heat exchanger warms the gas sample after pressure reduction; preventing condensation as the gas enters the sample transport system.

Single stage pressure regulator.

The Model GR™ Genie® Pressure Regulator is a single stage pressure regulator designed specifically for use in gas analyzer sample conditioning systems. Its stainless steel housing contains a piston style sensing element, increasing reliability and eliminating the chance for diaphragm rupture. Additionally, the low internal volume and unique interior design allow it to purge quickly.

Specifically designed for gas analytical systems.

The Model JTR-H™ is a revolutionary product containing four stages of heated pressure regulation in one 316 stainless steel housing. The design of the JTR-H™ separates it from current multi-stage heated regulators that are typically limited to two stages. Specifically designed for gas analytical systems, the JTR-H™ prevents condensation of the sample gas from occurring as a result of Joule-Thomson (JT) cooling during the pressure reduction process of high pressure and high dew point gases or due to low operating or ambient temperatures.

A stable outlet pressure, even through large swings in inlet pressure.

The Genie® Model JTR™ is a revolutionary product containing four stages of pressure regulation in one stainless steel housing, specifically designed for gas analytical systems. Gone are the days of having to purchase multiple pressure regulators and manifold them together in series.

The pressure regulation stages of the JTR™ employ a multi-piston design. The first three stages are ratio controlled and the fourth stage is user adjustable. The advantage of the ratio controlled piston design is that it ensures the first three stages are always functional, even when the inlet supply pressure fluctuates. No more headaches of having to constantly readjust the set pressure of each stage.

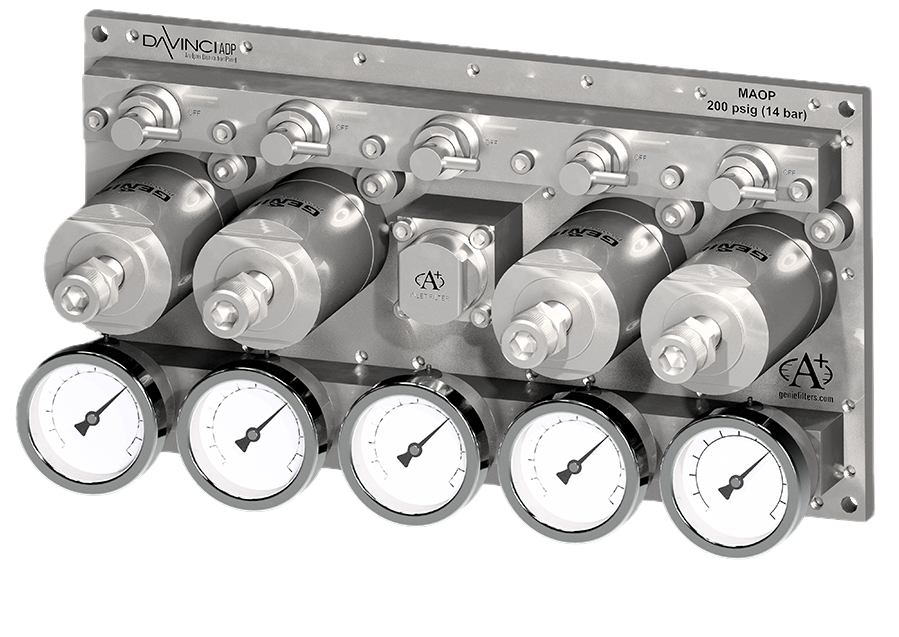

One gas sample stream in. Four low pressure gas streams out.

The DaVinci™ Modular Analyzer Distribution Panel (ADP) is a pre-packaged solution that makes it possible to supply up to four different analyzers with low pressure gas samples from a single source, eliminating the need to establish multiple sample points and reducing the cost of required sampling hardware.

The ADP consists of a single modular board with built in purge loop, inlet filter and gauge, integral stream isolation valves, and pressure regulators with their respective gauges. The standard ADP is supplied with one regulator and pressure gauge. Up to three additional regulators with respective gauges can be added and assembled on the board at the time of order or later in the field by the technician.

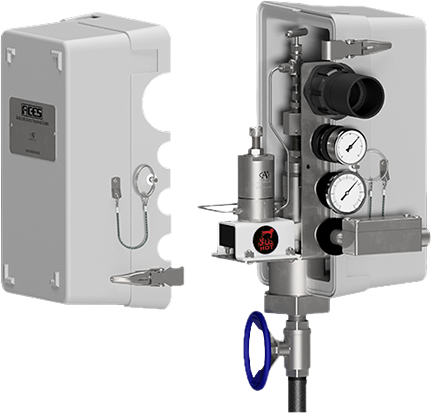

Tailored to your application.

Each Analytically Correct™ Engineered Sample System is designed to meet specific application needs; ensuring sample integrity is maintained throughout the sample extraction and preconditioning process. With a wide range of sampling equipment including our retractable sample probes using Genie® Membrane Technology™ to separate unwanted liquid aerosols and droplets from the gas sample at process conditions, to our innovative and patented 4-stage Joule Thomson Regulator that reduces the sample pressure while preventing condensation from occurring as a result of Joule-Thomson (JT) cooling, and lots of sample conditioning components in between to solve your applications. As the industry’s leading sampling experts, our revolutionary sample system design approach is the first of it’s kind to use Equations of State software to provide specific product recommendations ensuring the correct sampling system for your specific application.