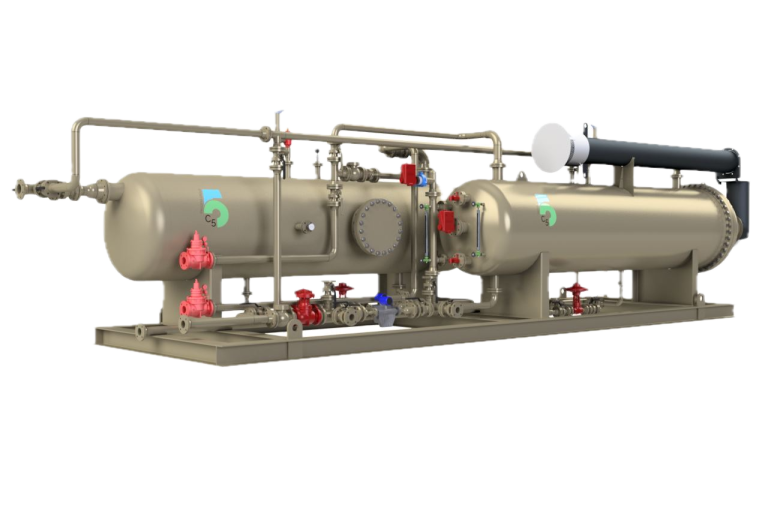

C5 Process Group, Inc. (C5PG) provides equipment to remove water from crude oil. Treating elements include heat, supplemental coalescing devices, and gravity settling. Typical treaters include corrugated plates, mesh pads, perforated plates, and slotted baffles. Treaters can be configured either horizontally or vertically, with U-type firetubes in the heating section and coalescing devices in the treating section.

Crude oils need to be free from water to diminish corrosion, shipping volume, transportation requirements and to eliminate water/oil emulsions. Enhanced coalescing devices accelerate the separation of water from the crude oil. Heat lowers the viscosity of the crude oil and provides turbulence and mixing of the chemical emulsion breakers to resolve dispersed water droplets in the crude. Most treaters are found in crude oil production.

Oil flows into the fired section where oil is thoroughly de-gassed and then flows horizontally and vertically through coalescing devices. The water droplets then coalesce and settle to the water/oil interface. The coalescing section is typically gas packed. Multiple firetubes sometimes are needed to achieve targeted heat duty.