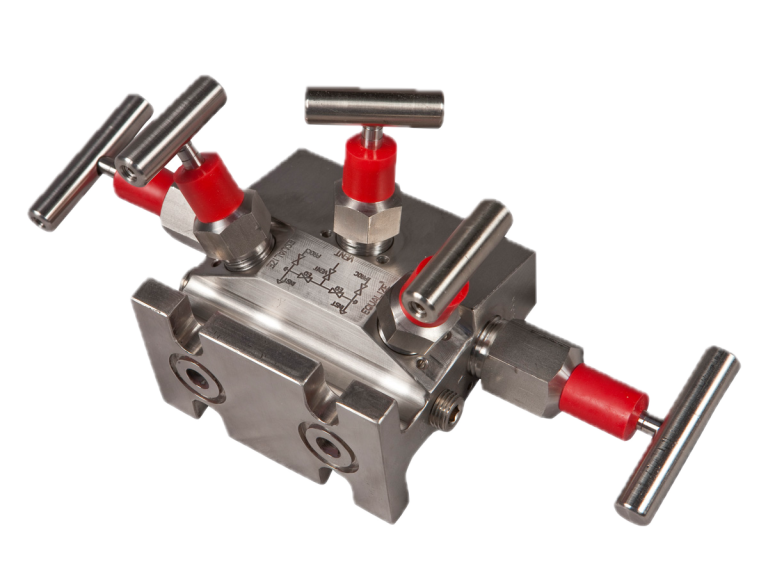

The new Kerotest 3/8-inch Large Bore Manifolds offer some major benefits over standard bore manifolds when used in on-shore and off-shore applications. By minimizing gauge line error, they ensure the accuracy of the measurement unit pressure readings that are used to calculate flow. And the improved line drainage eliminates problems associated with wet gases and hydrates.

Like standard Kerotest manifolds, these new Large Bore models are designed to capably perform isolation, equalization, bypass, test, and vent operations without the need for external piping, since the required piping is internal to the manifold.