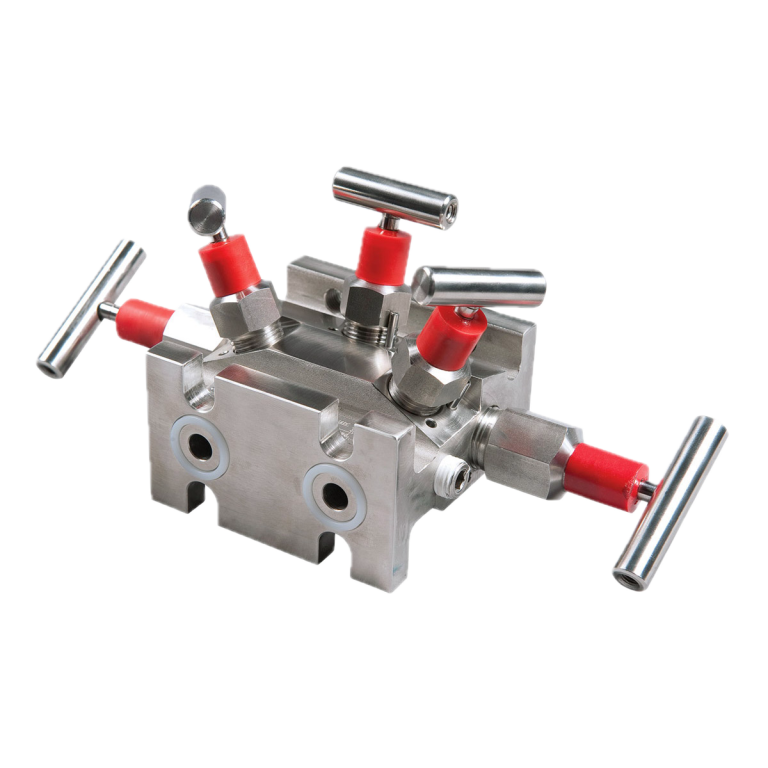

The KL Multi-Valve Manifold is designed specifically for natural gas applications, especially for use with recording orifice meters. The manifolds provide, in a single body, 3 or 5 valves for differential pressure measurement applications. This compact, industry standard-sized design results in fewer leaks to the environment. These manifolds have large 3/8″ (9.5mm) bores connecting the process and instrumentation sides. The manifolds are available in Pipe by Pipe, Pipe by Flange, Flange by Flange configurations with inline or right-angle process flows in stainless or carbon steel.

Features/Benefits:

- Lightweight construction. Installs in meter tubing without additional support.

- Tested and qualified. Cycle tested 500 times under full Cold Working Pressure (CWP) load.

- 1/4-inch FNPT ports standard. Connect static pressure to the upstream or downstream ports.

- Dual high-performance grade Viton™ O-Ring with PTFE backup ring packing design below stem threads.

- Metal-to-metal, bonnet-to-body seal to maintain shell pressure.

- Non-rotating taper tip stem plug design to reduce seat wear.

- Mirror internal bonnet finish for extended packing life.

- Bonnet cap protection. Increases valve life and maintains integrity of stem threads.

- No more stem blowouts. No-backout stem design prevents blowout problems and removal while in use.

- Ergonomic, non-knuckle busting handle positioning for smooth turns and accurate adjustments.

- Built in ISO 9001 certified facility.

- Compliance with industry standards (ASME B31.1, ASME B31.3, API 598, ISO 5208, and MSS SP-99.