Kerotest® Manufacturing

Serving the world’s energy markets.

Founded in 1909, Kerotest Manufacturing is recognized as an industry leader in the manufacturing and development of cutting edge gas distribution products. An Employee Stock Ownership Plan company, Kerotest has manufacturing plants in Pittsburgh, PA and Mansura, LA. Kerotest offers steel and polyethylene valves, electrofusion equipment, and industrial needle and manifold valves for various industries.

- 3/8-Inch Large Bore Manifolds

- Polyball® 12-Inch Full Port

- Polyball® Natural Gas Valves

- Weldball® Gas Distribution Valve

- Model-1 Weld By Flange

- EV-11 Soft Seated Gate Valves

- T-Strainers, Carbon Steel

- Gauge Valve / Block & Bleed

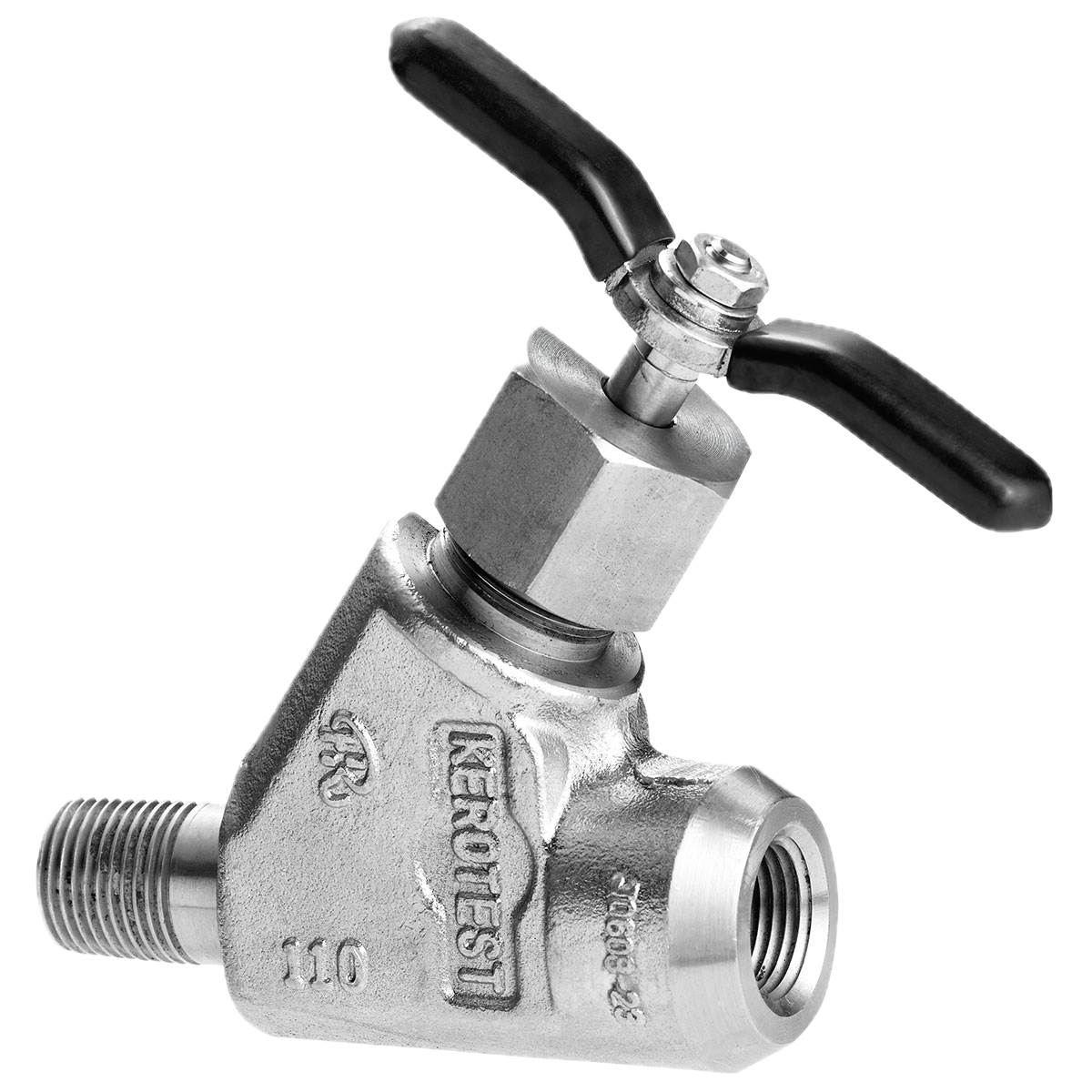

- 110 Gauge Shutoff Valve

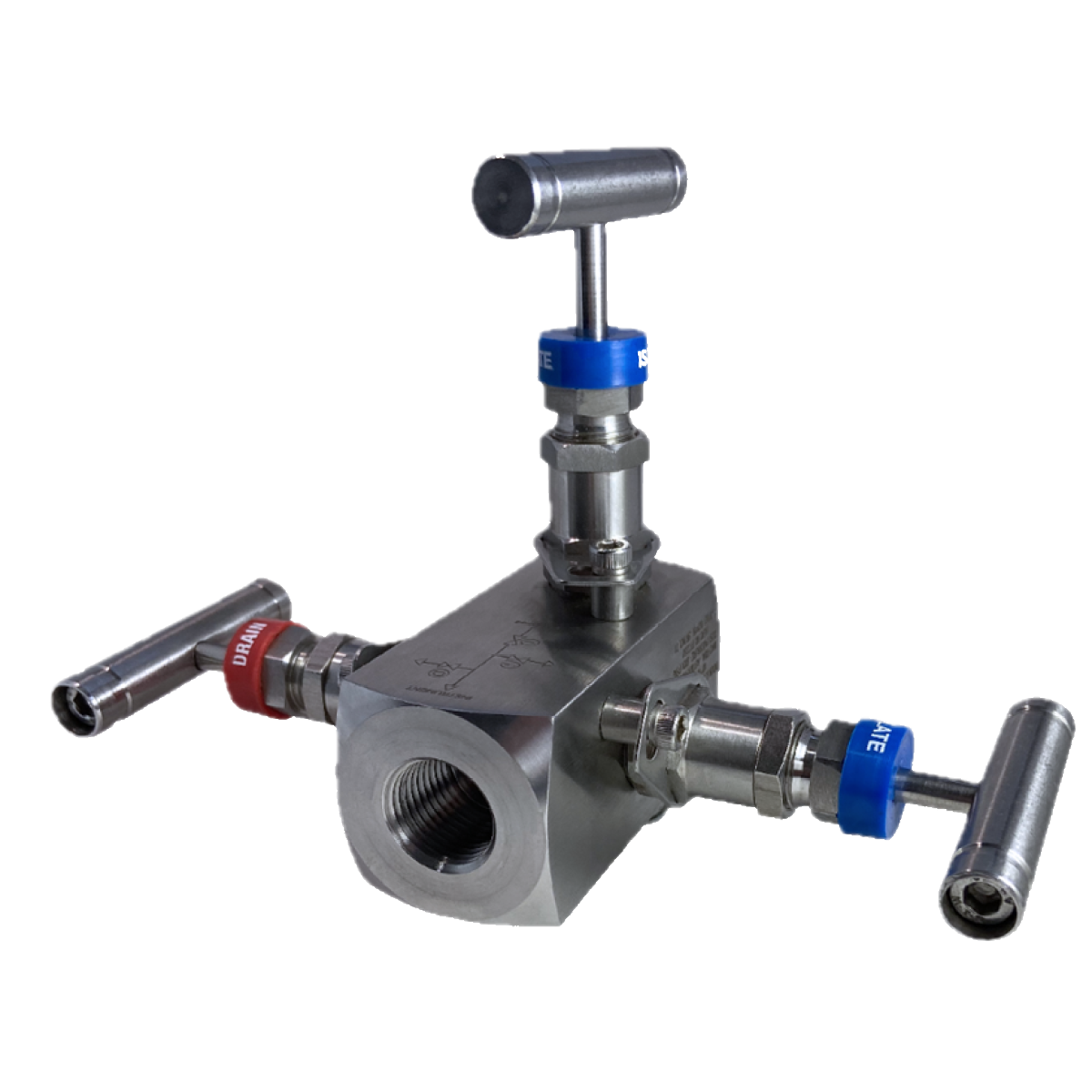

- Double Block & Bleed

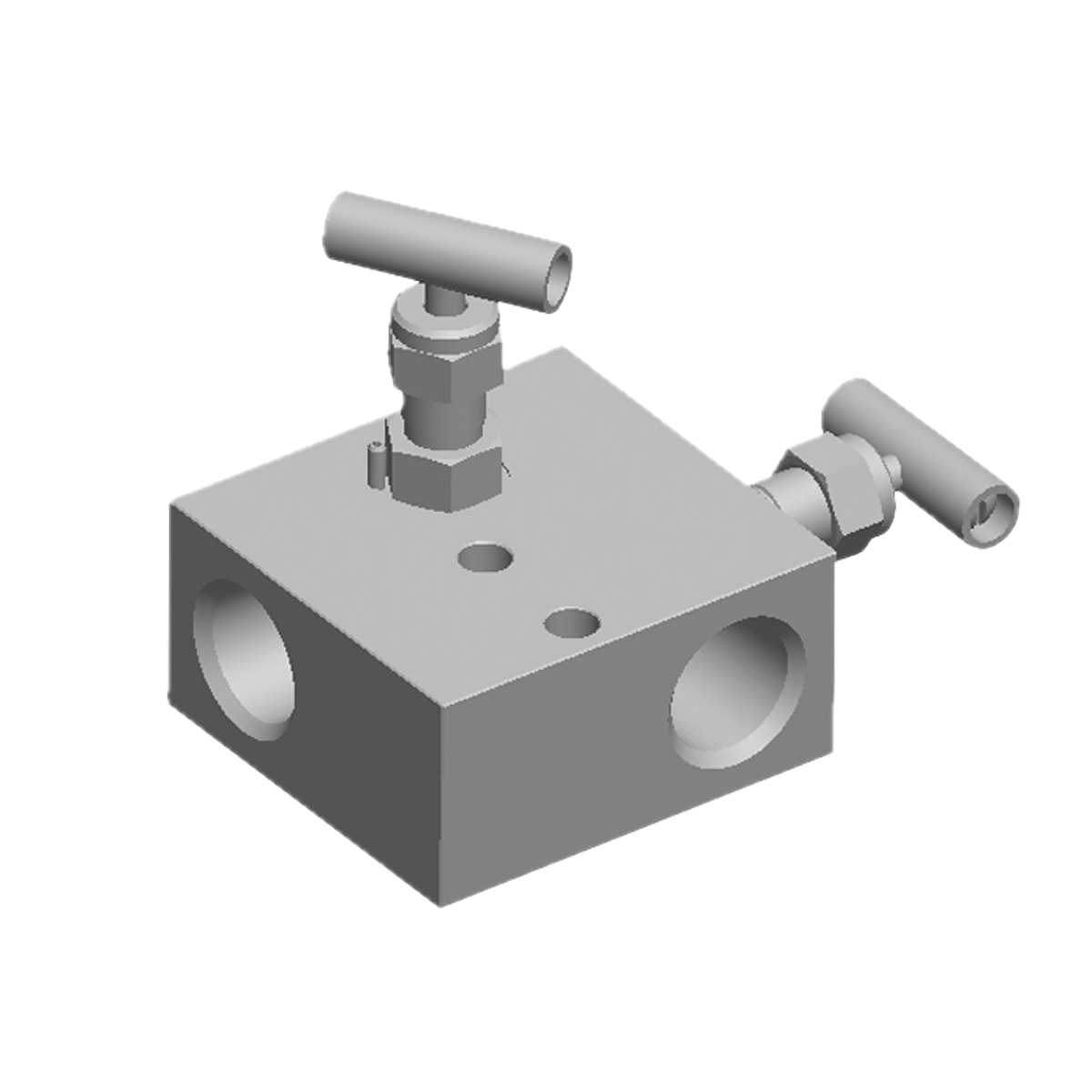

- KPTM & KPT7 2-Valve

- Model-1 Accessories

- Model-1 Weld By Flange

- Model-1 Flanged End

- Model-1 Short Weld End

- Model-1 Long Weld End

- Model-1 Screwed End

- 200 Gauge Shutoff Valve

- 300 Gauge Valve

- Manifold Accessories

- KM6A, KM6T, and KM6TA 5-Valve

- N20 In-Line Union Bonnet Needle Valve

- Portafuse® 4 Max

- N21 Angle Union Bonnet Needle Valve

- N28 Integral Union Bonnet Needle Valve

- N28 Soft Seated Needle Valve

- MIJ – Monolithic Isolation Joints

- Zunt Monolithic Insulating Joints

- Portafuse® 4 Lite

- Electrofusion Tooling & Accessories

- Electrofusion Fittings

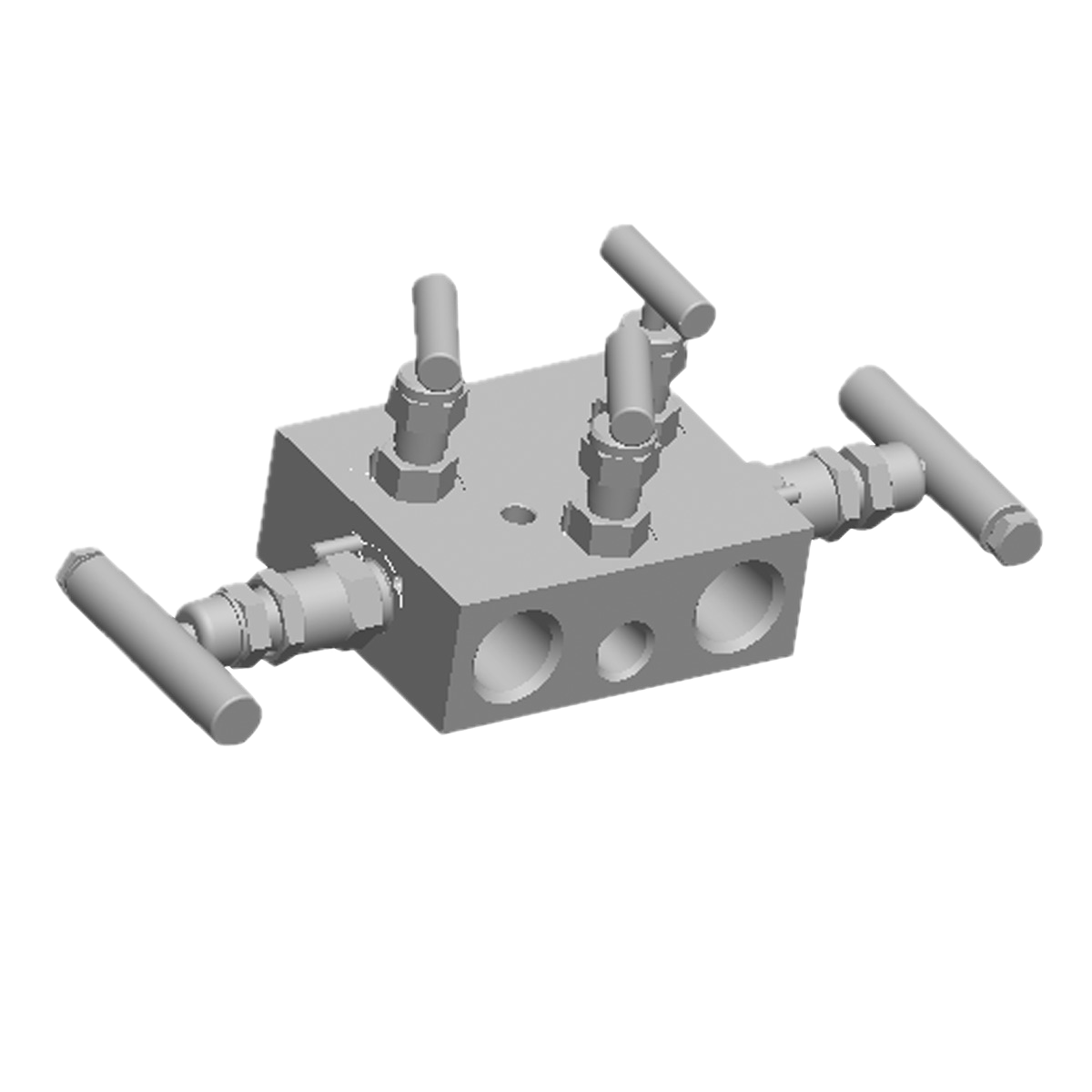

Major benefits over standard bore manifolds.

The new Kerotest 3/8-inch Large Bore Manifolds offer some major benefits over standard bore manifolds when used in on-shore and off-shore applications. By minimizing gauge line error, they ensure the accuracy of the measurement unit pressure readings that are used to calculate flow. And the improved line drainage eliminates problems associated with wet gases and hydrates.

Like standard Kerotest manifolds, these new Large Bore models are designed to capably perform isolation, equalization, bypass, test, and vent operations without the need for external piping, since the required piping is internal to the manifold.

Full port features a 10.1 inch port opening.

The Kerotest 12-inch Polyball full port polyethylene ball valve is big and it delivers big. This large bore model boasts the highest flow of any 12-inch polyethylene ball valve made in America today. It’s full of the big design, engineering and production benefits that have made us one of the leading manufacturers of polyethylene ball valves in North America.

Made in the USA to perform and comply.

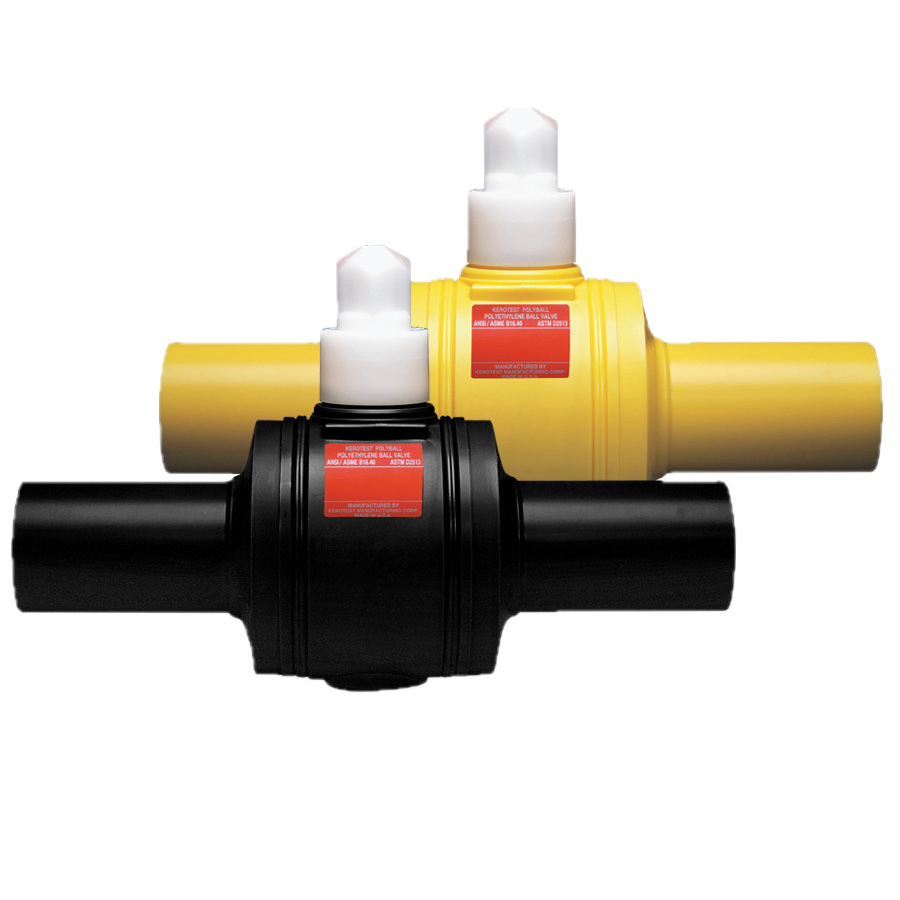

Kerotest Polyball polyethylene ball valves for natural gas reflect a 100-year commitment to the gas distribution industry. These valves are American made, supported and distributed, with ample inventory at all times. You will find full port and reduced port sizes from .5-inch to 12-inch IPS; metric sizes from 20mm to 315mm, and available High Head Extensions in varying heights to meet specific installation requirements.

All Polyball valves feature the industry-standard tracking and traceability code per ASTM F2897 that allows instant access to individual valve specifications. With decoding software, simply scan the bar code to see the production date, size, material and valve type, lot code and more.

Made in the USA to perform and comply.

In some of the most extensive tests performed on a valve, the Kerotest Weldball Gas Distribution Valve consistently meets and exceeds industry standards for design and performance.

The Weldball full port and reduced port valves come in butt weld, flange, and weld by flange configurations. Class 150 Reduced Port valves are available in sizes .75-inch through 12-inch, while the Full Port valves are available in 2-inch through 10-inch. Class 300 Reduced Port valves are available in sizes .75-inch through 8-inch, while Full Port valves are available in 2-inch thru 8-inch. And, of course you can count on zero leaks, no maintenance and no required lubrication or adjustments.

Each valve is high-pressure air tested to insure integrity and leak tightness. Use it with confidence in distribution services, meter and regulator stations, system blow down applications, hot tap applications and other applications that demand a positive shut-off.

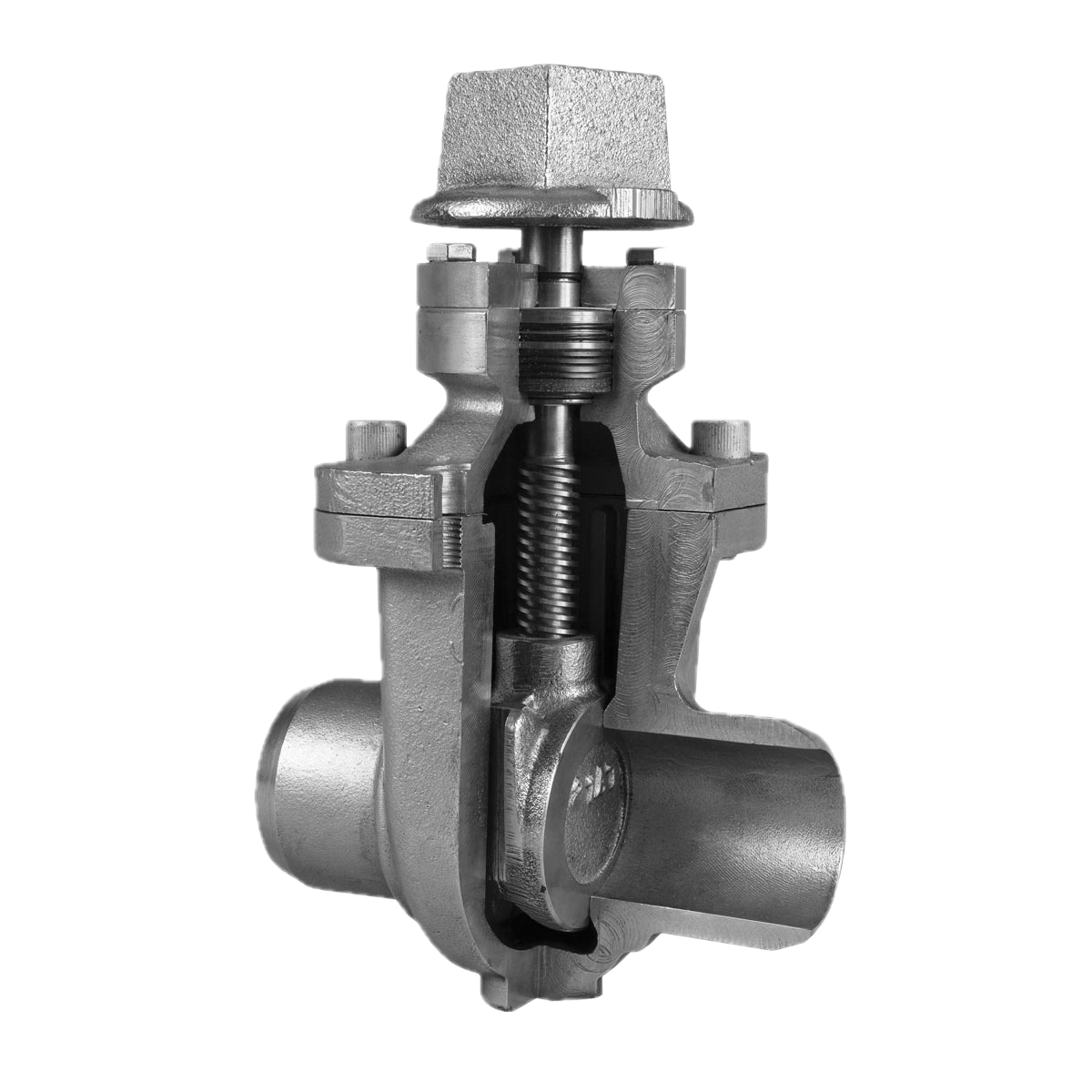

The lowest operating torque in the industry.

The Kerotest Model-1 Steel Gate Valves feature metal-to-metal seats, the lowest operating torque in the industry and a patented packing to ensure no environmental leakage. Choose from a full size range of 1-inch to 16-inch with a variety of end configurations and 285 to 740 WOG.

The Model-1 also features a full range of options and accessories that include watertight high head extensions, operating square extensions, malleable iron circular hand-wheels, epoxy coating, body bleed taps and vent pipes.

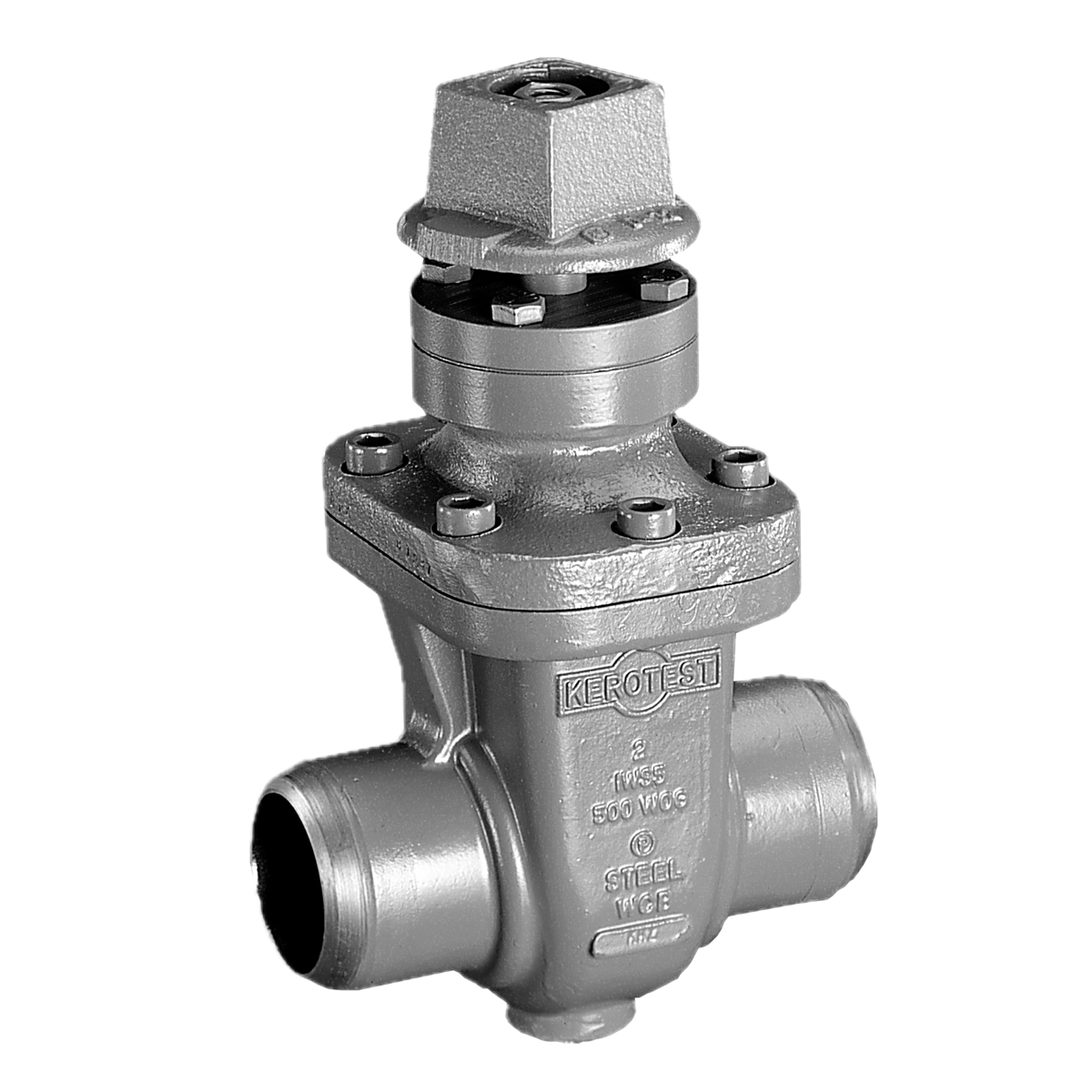

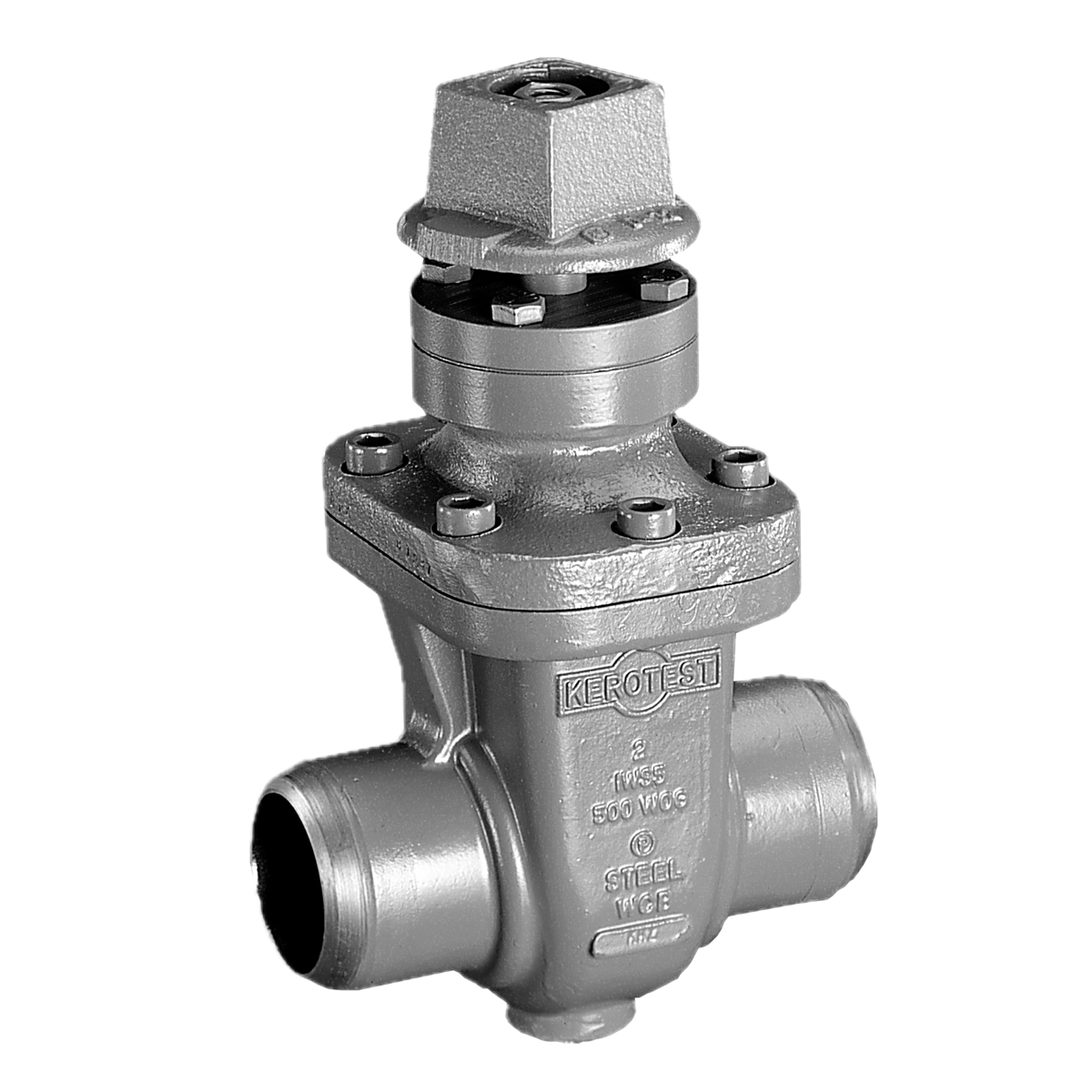

Ideal for natural gas distribution applications.

The EV-11 Soft Seated Valve is an economical field-proven, full opening, non-rising stem gate valve. This unusual gate valve incorporates an exclusive “elastomer seat” seat design – a simple method which solves leakage problems without requiring lubrication or conventional seat inserts. Available in 2-inch through 12-inch full port; Class 150, 500 WOG and Class 300; flange, weld and weld by flange end connections.

This remarkable general service valve is ideal for natural gas distribution applications including manifolds, flow lines, regulator stations, and meter runs. The full-opening, uncomplicated design of the EV-11 soft-seat gate valve makes it ideal for water, oil, and other liquid applications.

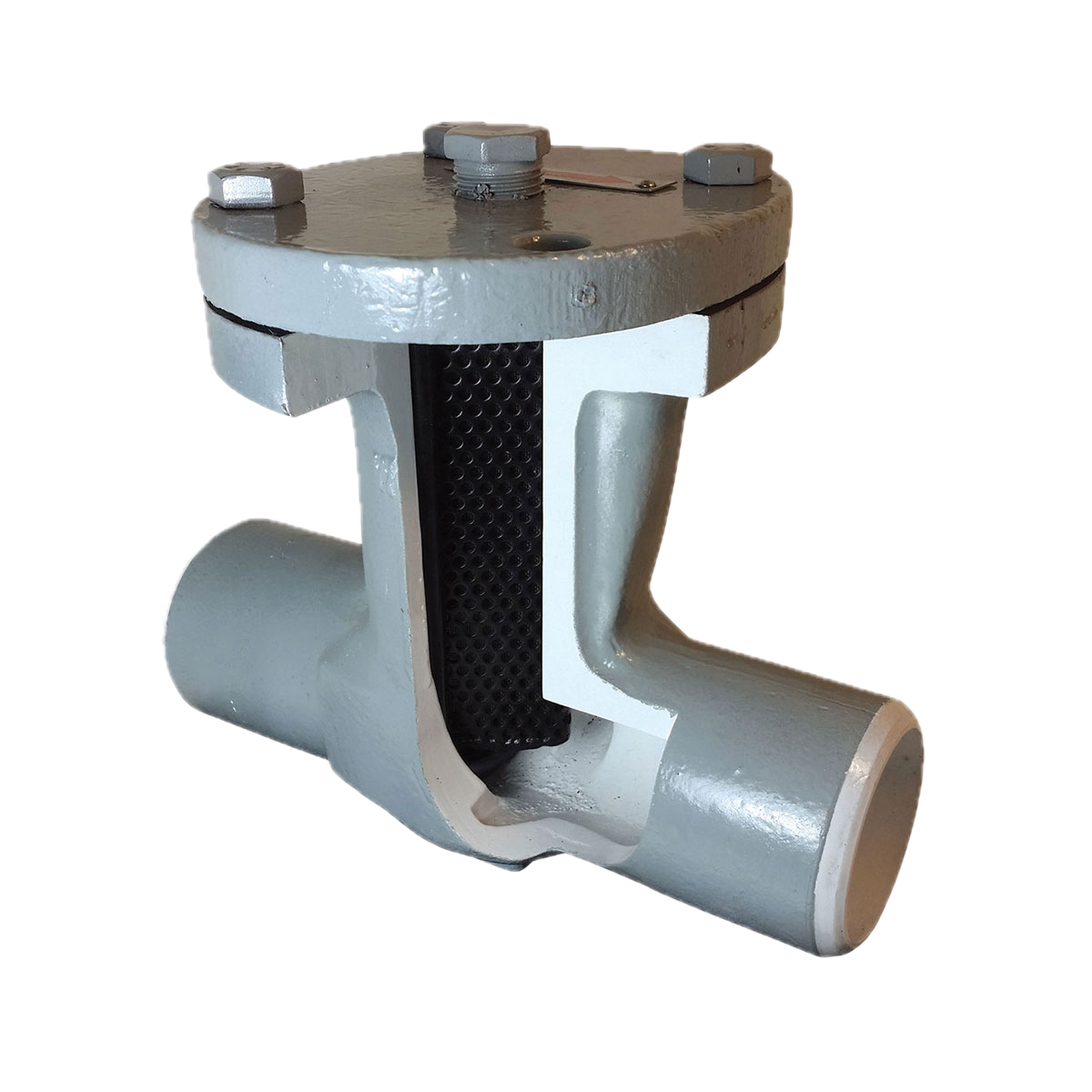

Manufactured of carbon steel to ensure strength, precision, and long-life.

These T-Strainers, which provide up to 30 percent larger basket area, are manufactured of carbon steel to ensure strength, precision, and long-life. Available in standard sizes from 1-inch through 6-inch, ANSI 150/300 pound, Kerotest can also deliver t-strainers in larger sizes as needed.

Kerotest T-Strainers are interchangeable in valves with Standard ANSI B16.5 & 16.10 end-to-end dimensions. They also feature an elastomeric basket seal that eliminates potential leakage between the basket and body, as well as a reversible basket that readily accommodates reverse flow applications.

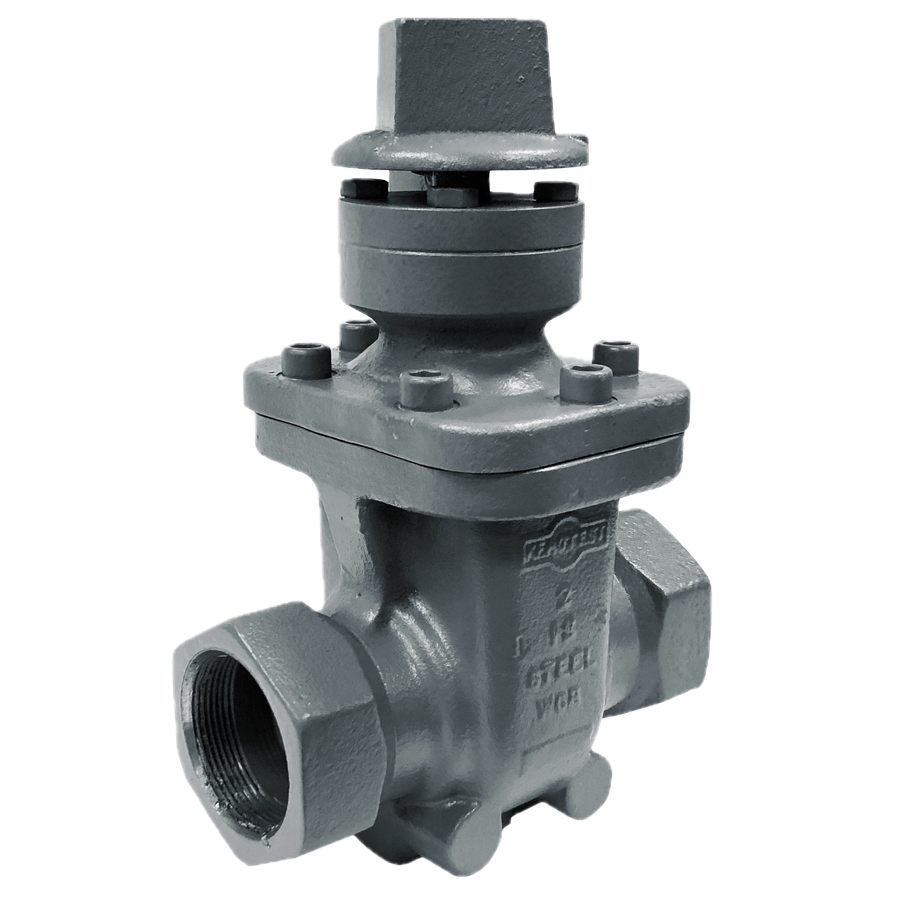

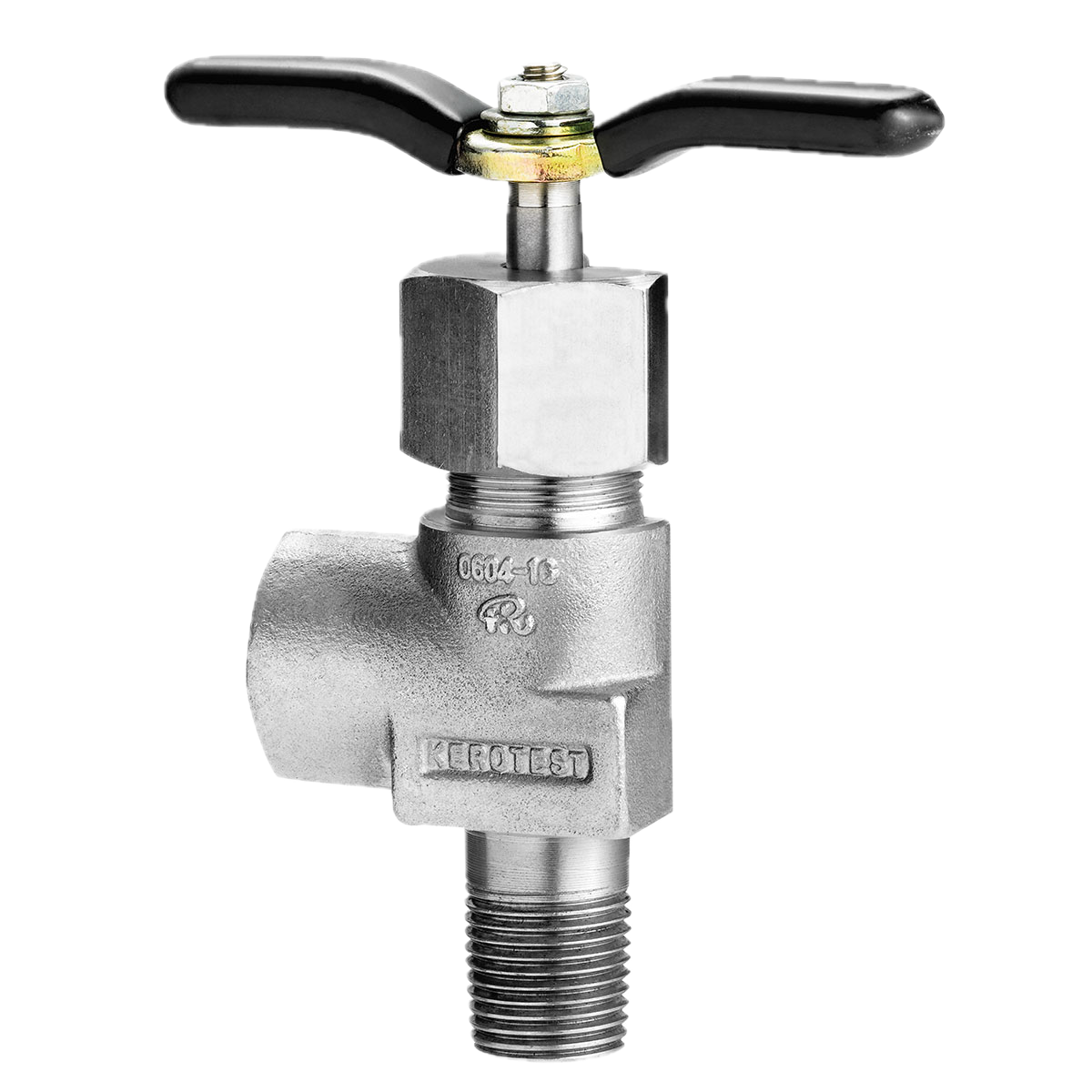

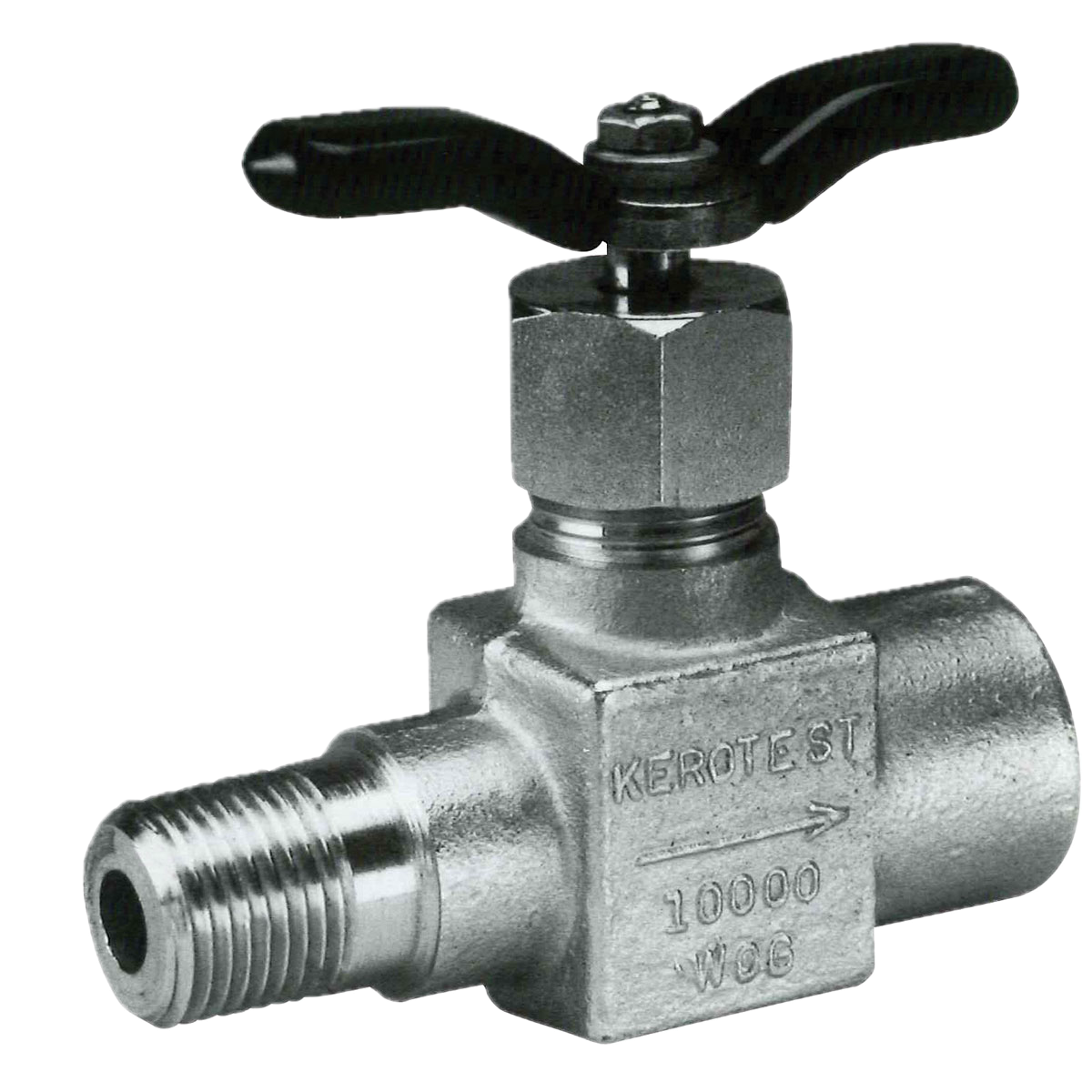

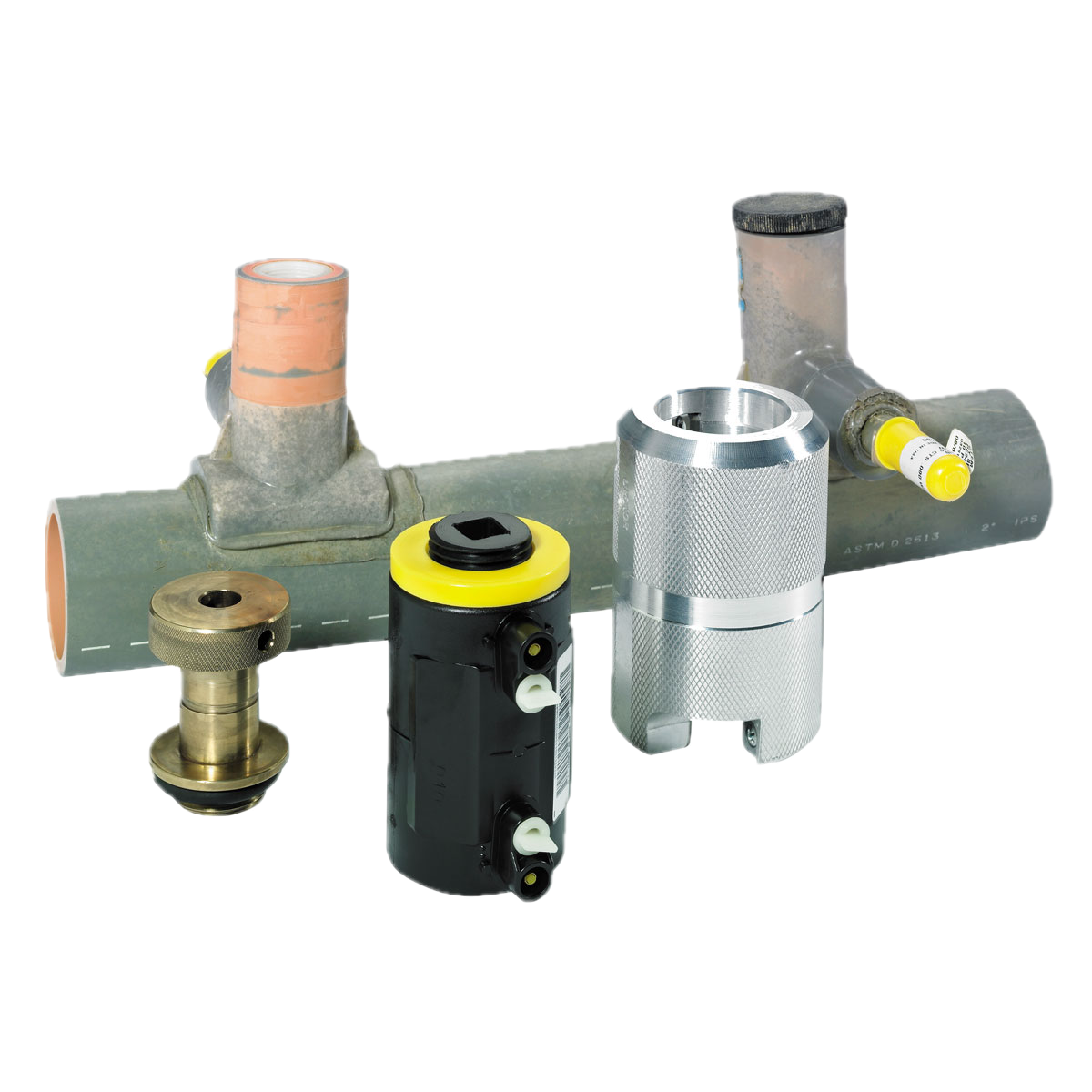

For use anywhere the flow of fluid must be carefully regulated.

These valves provide extra pressure outlets, permit line samplings, isolate gauges, provide a bypass, and eliminate extra connections and parts on a gauge leg, thereby reducing cost and increasing dependability. Kerotest/Marsh “N” Series Needle Valves are used in processing plants, oil and gas production, hydraulic and pneumatic equipment, testing labs—anywhere the flow of fluid must be carefully regulated.

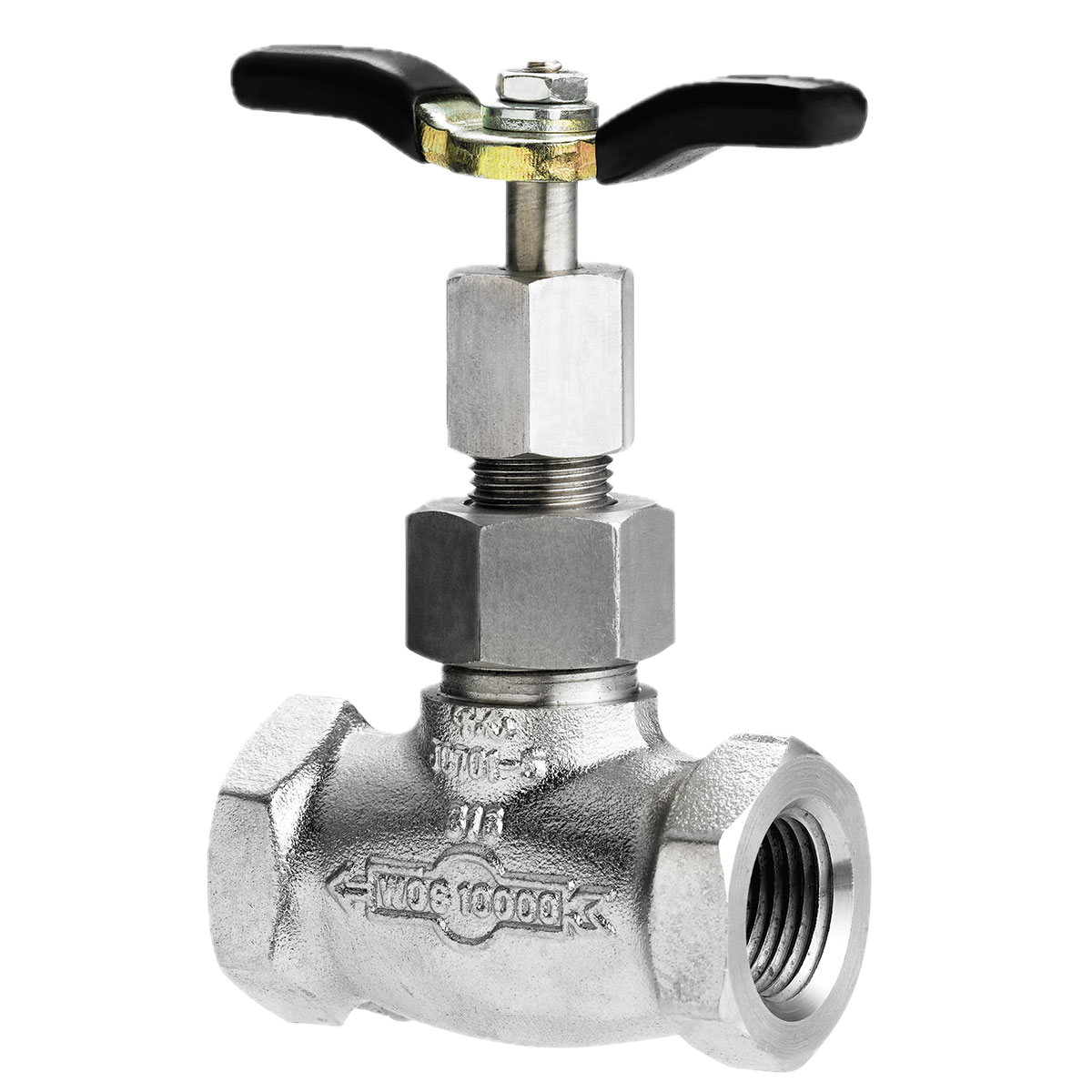

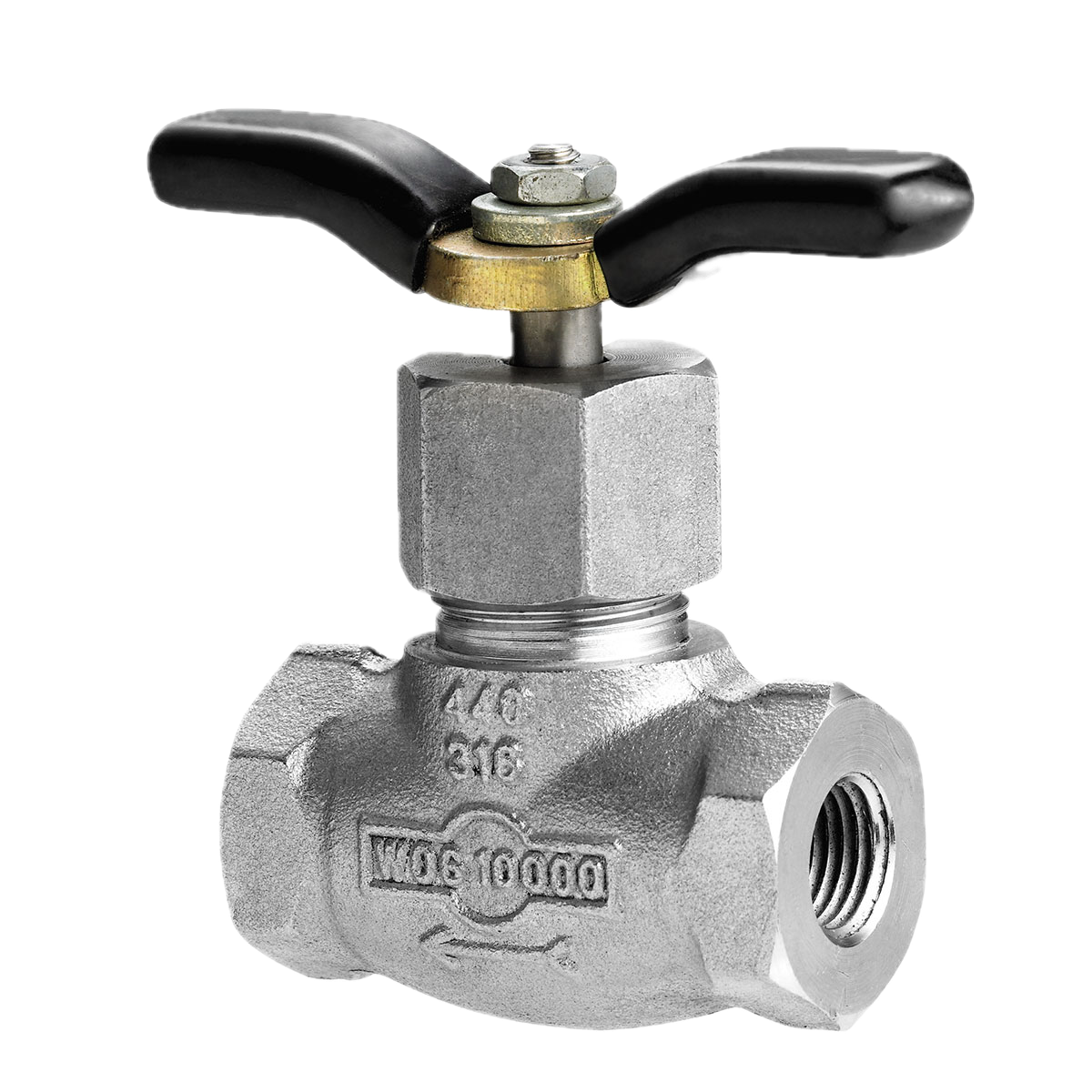

These valves perform in tight spaces and resist low-level corrosiveness.

A rugged, forged construction delivers dependable, leak-free performance at high and low pressures. Designed to measure and regulate flow in processing plants and oil and gas production applications, these valves perform in tight spaces and resist low-level corrosiveness. With optional trim, they also resist sour fluid environments, caustic liquids, and corrosive media.

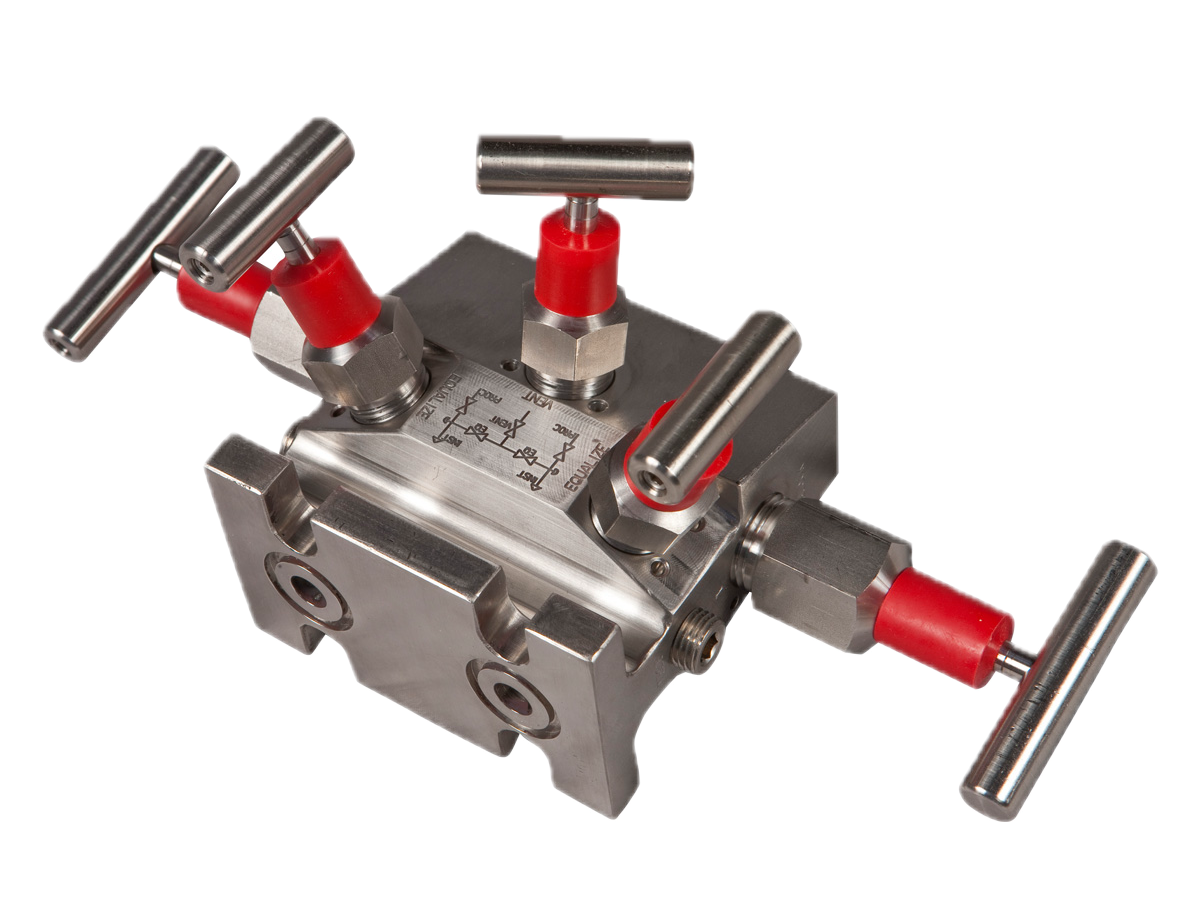

Built for applications with pressures up to 10,000 psig.

The Kerotest Double Block & Bleed Needle Valves are built for applications with pressures up to 10,000 psig (689 bar). The design combines isolation and venting in a single valve, eliminating the need for tubing and fittings. This operator-friendly valve design features fully captured stems, consistent sealing during system depressurization or repressurization under a range of pressures, and a low-torque, easy-turn ergonomic handle.

Used primarily to calibrate static pressure transmitters, switches, or gauges.

The KPT two-valve manifolds are used primarily to calibrate static pressure transmitters, switches, or gauges. All necessary hardware including a shutoff valve, calibration valve, tee, and other tubing are all contained in one product. The KPT series of manifolds are available with either replaceable soft seats or an integral metal seat. The KPTM manifold includes a special valve seat that can be converted from a hard or metal seat to a soft seat by simply removing two washers. The KPT7 manifold is intended for high temperature applications. It has an integral metal seat.

We offer a full complement of options and accessories.

The Kerotest Model 1 Steel Gate Valves feature metal-to-metal seats, the lowest operating torque in the industry and a patented packing to ensure no environmental leakage. Along with a 1-inch to 16-inch size range, a variety of end configurations and 285 to 740 WOG, we offer a full complement of options and accessories.

Customize your gate valves with locking devices, watertight high head extensions, operating square extensions, malleable iron circular hand-wheels, indicators, epoxy coating, body bleed taps, and vent pipes.

Patented packing to ensure no environmental leakage.

The Kerotest Model-1 Steel Gate Valves feature metal-to-metal seats, the lowest operating torque in the industry and a patented packing to ensure no environmental leakage. Choose from a full size range of 1-inch to 16-inch with a variety of end configurations and 285 to 740 WOG.

The Model-1 also features a full range of options and accessories that include watertight high head extensions, operating square extensions, malleable iron circular hand-wheels, epoxy coating, body bleed taps and vent pipes.

A full range of options and accessories.

The Kerotest Model-1 Steel Gate Valves feature metal-to-metal seats, the lowest operating torque in the industry and a patented packing to ensure no environmental leakage. Choose from a full size range of 1-inch to 16-inch with a variety of end configurations and 285 to 740 WOG.

The Model-1 also features a full range of options and accessories that include watertight high head extensions, operating square extensions, malleable iron circular hand-wheels, epoxy coating, body bleed taps and vent pipes.

Short weld end, natural gas.

The Kerotest Model-1 Steel Gate Valves feature metal-to-metal seats, the lowest operating torque in the industry and a patented packing to ensure no environmental leakage. Choose from a full size range of 1-inch to 16-inch with a variety of end configurations and 285 to 740 WOG.

The Model-1 also features a full range of options and accessories that include watertight high head extensions, operating square extensions, malleable iron circular hand-wheels, epoxy coating, body bleed taps and vent pipes.

Long weld end, natural gas.

The Kerotest Model-1 Steel Gate Valves feature metal-to-metal seats, the lowest operating torque in the industry and a patented packing to ensure no environmental leakage. Choose from a full size range of 1-inch to 16-inch with a variety of end configurations and 285 to 740 WOG.

The Model-1 also features a full range of options and accessories that include watertight high head extensions, operating square extensions, malleable iron circular hand-wheels, epoxy coating, body bleed taps and vent pipes.

Long weld end, natural gas.

The Kerotest Model-1 Steel Gate Valves feature metal-to-metal seats, the lowest operating torque in the industry and a patented packing to ensure no environmental leakage. Choose from a full size range of 1-inch to 16-inch with a variety of end configurations and 285 to 740 WOG.

The Model-1 also features a full range of options and accessories that include watertight high head extensions, operating square extensions, malleable iron circular hand-wheels, epoxy coating, body bleed taps and vent pipes.

These valves perform in tight spaces and resist low-level corrosiveness.

A rugged, forged construction delivers dependable, leak-free performance at high and low pressures. Designed to measure and regulate flow in processing plants and oil and gas production applications, these valves perform in tight spaces and resist low-level corrosiveness. With optional trim, they also resist sour fluid environments, caustic liquids, and corrosive media.

A rugged, forged construction delivers dependable performance.

A rugged, forged construction delivers dependable, leak-free performance at high and low pressures. Designed to measure and regulate flow in processing plants and oil and gas production applications, these valves perform in tight spaces and resist low-level corrosiveness. With optional trim, they also resist sour fluid environments, caustic liquids, and corrosive media.

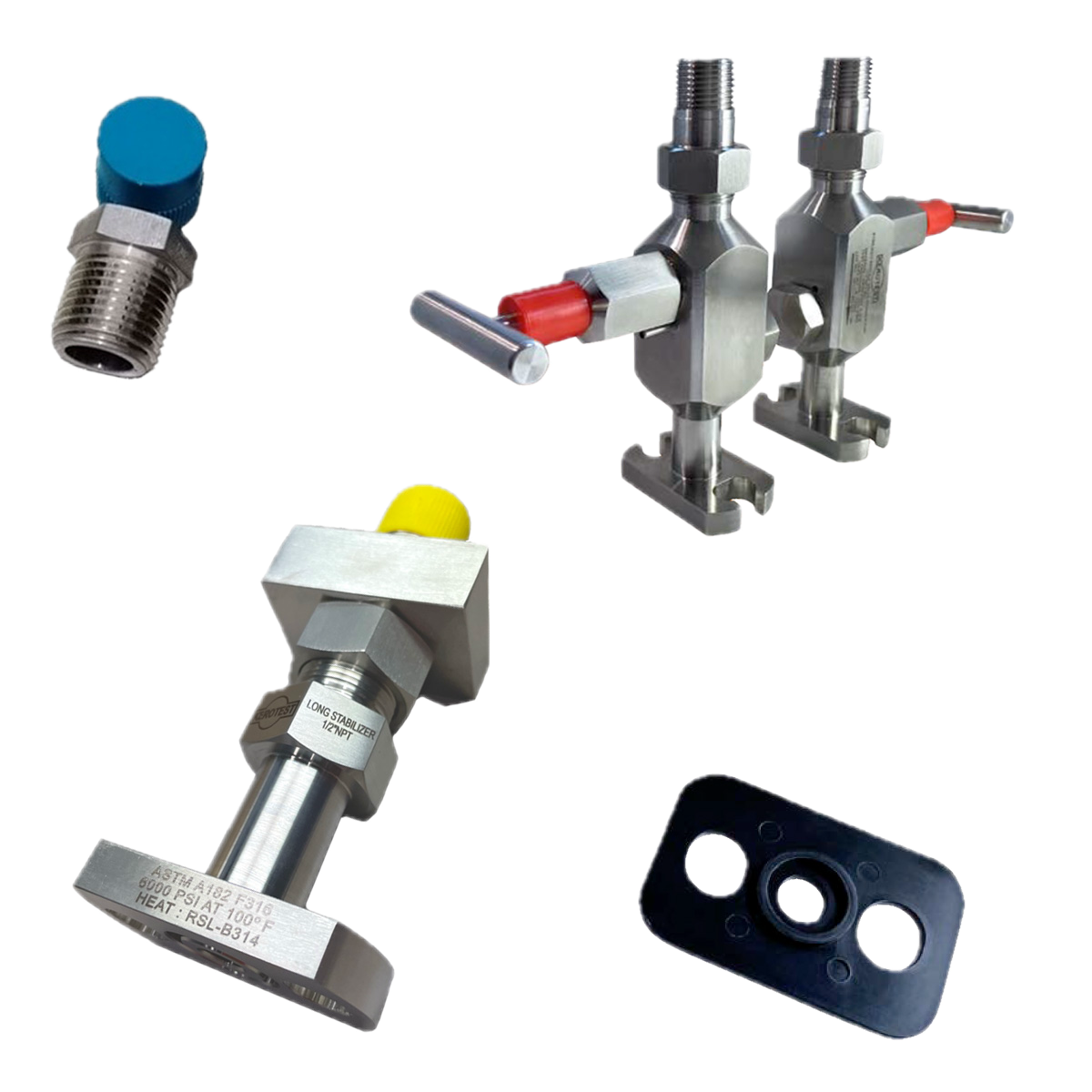

Kerotest manifold valve accessories.

Accessories such as mounting stabilizers, stabilizers with integrated block valve, dielectric isolation kits, and vent plugs.

Designed specifically for natural gas applications.

The KM6A 5-Valve Manifold is designed specifically for natural gas applications, especially for use with recording orifice meters. These manifolds are generally mounted in the tubing from the orifice flange. Because of its light weight, it is normally supported by the meter tubing without additional support. The KM6T and KM6TA options, however, allow for flange-by-tube installation or flange-by-flange installation of these manifolds if desired.

Rugged, forged construction.

A rugged, forged construction delivers dependable, leak-free performance at high and low pressures. Designed to measure and regulate flow in processing plants and oil and gas production applications, these valves perform in tight spaces and resist low-level corrosiveness. With optional trim, they also resist sour fluid environments, caustic liquids, and corrosive media.

Designed to fulfill all typical gas utility applications without generators and extension cords.

Portafuse® 4 Max takes the Portafuse® line of machines brought to you by Kerotest to a new level. The lithium-Ion 32 AMP hour powerpack is designed to fulfill all typical gas utility applications without generators and extension cords.

Leak-free performance at high and low pressures.

A rugged, forged construction delivers dependable, leak-free performance at high and low pressures. Designed to measure and regulate flow in processing plants and oil and gas production applications, these valves perform in tight spaces and resist low-level corrosiveness. With optional trim, they also resist sour fluid environments, caustic liquids, and corrosive media.

These valves perform in tight spaces.

A rugged, forged construction delivers dependable, leak-free performance at high and low pressures. Designed to measure and regulate flow in processing plants and oil and gas production applications, these valves perform in tight spaces and resist low-level corrosiveness. With optional trim, they also resist sour fluid environments, caustic liquids, and corrosive media.

Stainless steel and clear zinc plating.

A rugged, forged construction delivers dependable, leak-free performance at high and low pressures. Designed to measure and regulate flow in processing plants and oil and gas production applications, these valves perform in tight spaces and resist low-level corrosiveness. With optional trim, they also resist sour fluid environments, caustic liquids, and corrosive media.

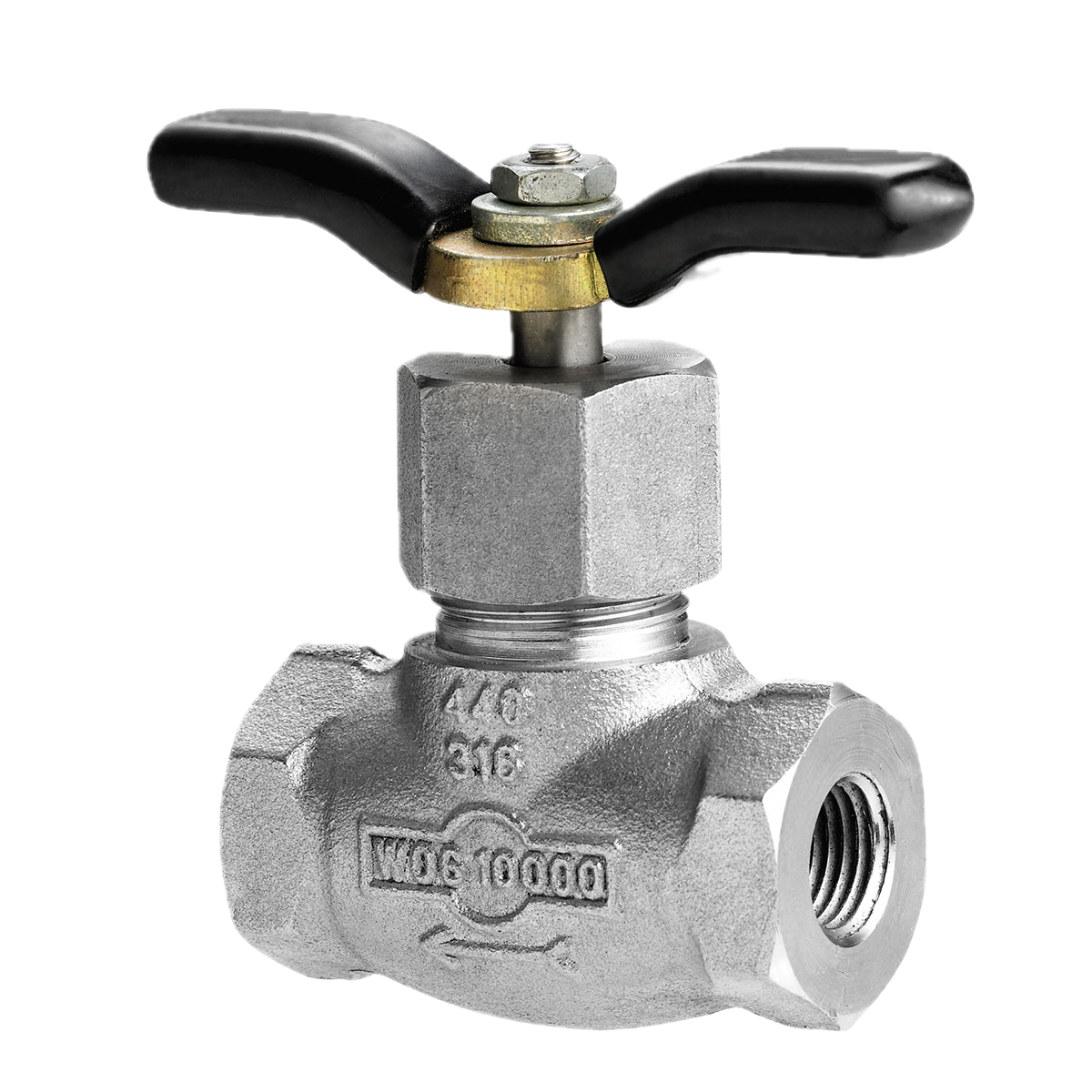

Designed for the most demanding cathodic applications.

The Kerotest MIJ Insulators bring the highest quality monolithic isolation joint manufacturing and assembly capabilities to North America. MIJ Monolithic Isolation Joints, assembled right here in the U.S., use advanced corrosion prevention technology, testing equipment, tracking procedures, materials and coatings. The quality management system of our Mansura, Louisiana facility meets the requirements of ISO 9001:2015, and now houses Kerotest’s new MIJ manufacturing operations. With this new state-of-the-art equipment and capability, our customers will benefit from short lead times, ready inventory and reduced shipping costs.

Manufactured to ISO 9001 quality standards.

The Kerotest Zunt Insulating Joints are manufactured to ISO 9001 standards. This solid weld design is more economical and comes in a broader range than any previous insulating joint from Kerotest…from 1/2-inch to 120-inch and over, ANSI 150 to 2500. There is no assembly required and no maintenance.

Ideally suited to NG utility service and light operation applications.

Portafuse® 4 Lite is the next generation of the Portafuse line of machines brought to you by Kerotest. The upgraded power pack uses lithium power technology to lower weight and increase this trusted tool’s reliability. Portafuse Lite is ideally suited to NG utility service and light operation applications.

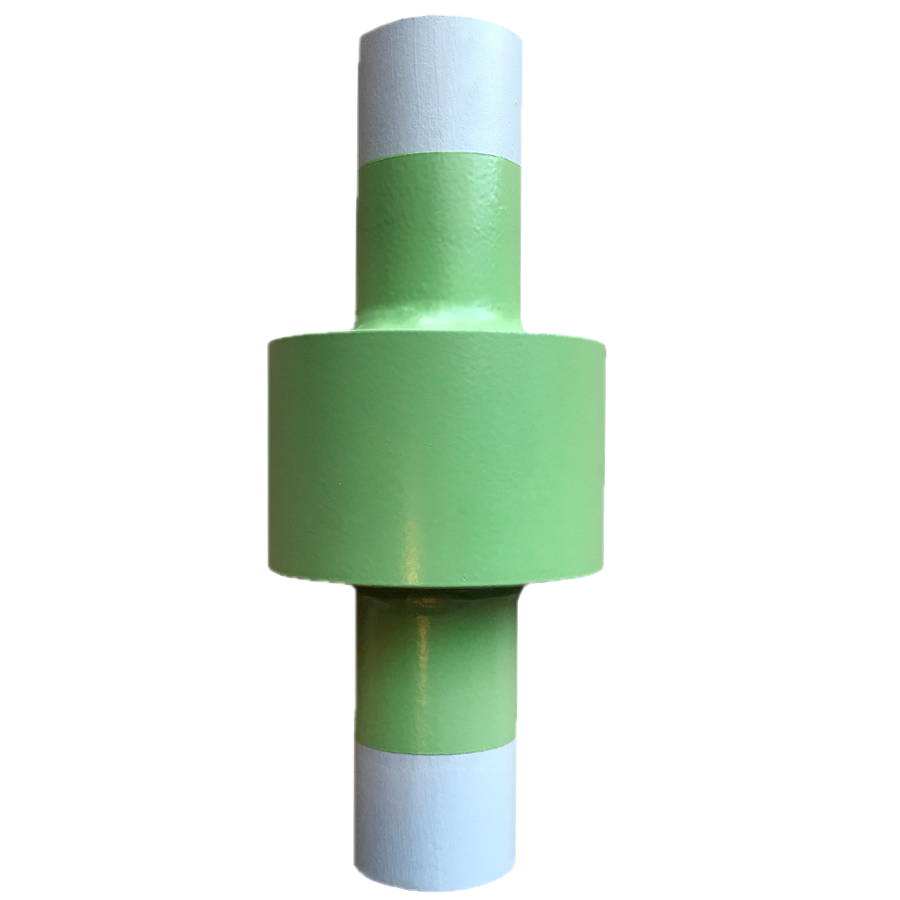

High quality. Ready inventory.

Kerotest offers a complete array of electrofusion tooling accessories that include polyethylene pipe scraping and peeling tools, positioning-alignment clamps, service line alignment clamps, PE pipe cutters, and tapping tee pipe perforator tools.

Learn more about the high quality, ready inventory, quick turnaround, and competitive prices that are built into all Kerotest valves and equipment.

Electrofusion couplings, tapping tees, saddles.

ALIAXIS fittings (couplings, tapping tees, saddles) are universal bar-coded for ease of installation and quality control. They also now feature the industry tracking and traceability code per ASTM F2897. We also offer a full line of PE 4710 couplings and tapping tees.

Learn more about the high quality, ready inventory, quick turnaround, and competitive prices that are built into all Kerotest valves and equipment.